In This Article:

Reducing packaging costs is a critical strategy for ecommerce businesses aiming to maximize profit margins. Packaging expenses encompass various elements, including materials, design, printing, and labor. Focusing on effective cost-reduction tactics can significantly boost profits.

Key Takeaway: Cutting down on the expenses associated with packaging your products can significantly boost your profits.

The insights shared in this blog come from industry experts at One World Direct, a leading ecommerce fulfillment company. With decades of experience in D2C and B2B order fulfillment, One World Direct has developed streamlined solutions to help businesses like yours optimize packaging processes while maintaining quality and brand integrity.

Understanding Packaging Costs and Its Impact on Profitability

The cost of packaging a product is complex and includes various factors like materials, design, printing, and labor. Businesses must understand these elements to optimize their expenses.

Key Components of Packaging Costs

- Materials: The type of material you choose—be it cardboard, plastic, or biodegradable options—significantly impacts the total cost. Premium materials offer durability but come at a higher price.

- Design: Complex designs that require custom molds or intricate printing can escalate costs. Simpler designs often provide a cost-effective solution without compromising brand impact.

- Printing: High-quality printing techniques such as embossing or foil stamping add to the expenses. Businesses should evaluate if these are essential for their brand identity.

- Labor: Manual packing processes are labor-intensive and costly. Automation can reduce these expenses while increasing efficiency.

Factors Contributing to High Packaging Expenses

Several factors contribute to high packaging expenses:

- Premium Materials: Opting for high-end materials elevates costs but may be necessary for certain product types that require superior protection.

- Complex Designs: Custom shapes and sizes can be appealing, but they also increase the overall expense due to specialized production requirements.

Packaging materials play a crucial role in determining overall costs. Striking a balance between quality and affordability is essential. For instance, using recycled cardboard instead of virgin material can cut costs without sacrificing protection.

Excessive packaging costs can eat into profit margins and hinder business growth. Reducing the cost of a product’s packaging can lead to higher profits by freeing up resources that can be reinvested into other business areas.

By understanding the various components and factors contributing to packaging costs, businesses can make informed decisions that positively impact their bottom line. Utilizing 3PL services could streamline logistics and potentially reduce costs significantly. Moreover, implementing strategies like batch picking or kitting services can further enhance efficiency in handling products.

It’s also crucial to consider the implications of packaging on ecommerce return rates, as excessive or unsuitable packaging can lead to increased returns. Finally, understanding how to reduce logistics costs is another vital aspect that businesses should focus on in their quest for profitability.

Choosing the Right Packaging Materials for Your Business Needs

Selecting the appropriate packaging materials is crucial for balancing cost, protection, and brand image. The most common types of packaging materials used in ecommerce include:

- Corrugated Cardboard: Offers excellent protection and customization options. While it is cost-effective and recyclable, it can be bulkier compared to other materials.

- Poly Mailers: Lightweight and water-resistant, ideal for soft goods like apparel. Poly mailers are generally cheaper to ship but offer limited protection compared to boxes.

- Shrink Wrap: Versatile and offers a tight seal around products. It’s effective for bundling items but may not provide sufficient cushioning on its own.

Sustainable Packaging Options

Using sustainable packaging materials not only benefits the environment but can also enhance your brand’s reputation. Options include:

- Recycled Cardboard: Maintains durability while reducing environmental impact.

- Biodegradable Packing Peanuts: Made from natural sources like corn starch, they dissolve in water and are non-toxic.

- Compostable Mailers: Designed to break down in composting facilities, these mailers align with eco-friendly brand values.

Sustainable options often have higher upfront costs, but they can lead to long-term savings through customer loyalty and reduced waste disposal fees.

Impact Protection Materials

Adequate protection during transit is essential to minimize returns and maintain customer satisfaction. High-quality yet cost-effective solutions include:

- Bubble Wrap: Provides superior impact protection. However, it adds to material costs and isn’t environmentally friendly unless you opt for biodegradable versions.

- Air Pillows: Lightweight and provide excellent cushioning. They occupy less storage space compared to alternatives like foam peanuts.

- Recycled Paper Fillers: Eco-friendly and versatile for filling voids in packages, though they might not offer the same level of shock absorption as air pillows or bubble wrap.

Choosing custom packing materials that balance cost and performance ensures your products arrive safely without unnecessarily inflating expenses. The right selection can significantly contribute to both profitability and customer satisfaction.

However, poor packaging choices can lead to damaged goods or incorrect items being sent. Furthermore, your choice of packaging materials can affect the successful management of inventory. For instance, using bulkier packaging like corrugated cardboard could pose challenges in inventory management, as it requires more storage space.

In addition, partnering with a reliable logistics provider can help streamline your operations. Knowing how to choose a 3PL provider that aligns with your packaging needs can significantly improve your supply chain efficiency.

By carefully evaluating your packaging needs against these criteria, you can make informed decisions that benefit your bottom line and brand integrity.

4 Effective Strategies to Reduce Packaging Costs Without Compromising Quality

1. Improve Package Design for Cost Savings and Brand Impact

Optimizing package design is crucial for reducing packaging expenses while maintaining a strong brand presence. By refining the size and shape of your packages, you can achieve significant cost savings in transportation and storage. Smaller, more efficiently designed packages reduce the amount of space occupied during shipping, thus lowering freight costs.

Key Considerations:

- Size Optimization: By minimizing the dimensions of your packaging, you not only save big on material costs and production time.

- Shape Efficiency: Designing packages that are stackable and fit well within standard master cartons can lead to more efficient stacking and better space utilization in warehouses and during transport.

Case Studies:

- IKEA: Known for its flat-pack furniture, IKEA has revolutionized packaging design by optimizing product dimensions to fit into flat boxes. This approach has reduced shipping costs and allowed more efficient use of storage space.

- Dell: Dell redesigned its laptop packaging to be smaller and lighter by using innovative materials like bamboo and mushroom packaging instead of traditional foam. This change has led to significant reductions in both material costs and environmental impact.

2. Optimizing Package Sizes to Minimize Dimensional Weight Charges

Dimensional weight charges are based on package dimensions rather than just actual weight, which can significantly impact shipping costs for lightweight but bulky items like pillows. To reduce these charges, it’s essential to focus on minimizing excess space within packages.

Key Strategies:

- Void Fill Elimination: Design custom-sized packages to eliminate unnecessary void fill materials, reducing wasted space and avoiding additional dimensional weight charges.

- Custom-Sized Boxes: Invest in equipment that creates custom-sized boxes tailored to each shipment, ensuring a snug fit and reducing dimensional weight.

- Optimized Packing Techniques: Use tailored inserts or dividers that securely hold products without adding bulk.

Examples of Cost-Saving Measures:

- Pillows and Blankets: Vacuum-sealed bags can shrink their size, reducing dimensions and shipping costs.

- Electronics: Thin foam inserts provide protection without increasing package volume.

Benefits:

- Cost Savings: Minimizing package size directly lowers shipping fees by reducing dimensional weight.

- Improved Customer Experience: Efficient packaging ensures products arrive intact and are well-presented, enhancing customer satisfaction.

By optimizing packaging, you can reduce shipping costs while maintaining product integrity and improving the overall customer experience.

3. Choosing the Right Materials That Balance Cost and Performance

Selecting appropriate materials is crucial for achieving long-term savings in packaging without compromising product protection or presentation quality. The key to packaging cost reduction lies in the strategic choice of materials that are both cost-efficient and durable.

Cost-effective Material Choices:

- Recycled Cardboard: One of the most constructive strategies for packaging cost reduction involves opting for recycled cardboard instead of new material. Recycled cardboard provides robust protection while being significantly more affordable and environmentally friendly.

- Thinner Plastic Films: Utilizing thinner plastic films can also be a viable option. These materials maintain adequate protection levels while reducing costs associated with raw material usage.

Importance of Material Selection:

- Long-term Savings: By choosing low-cost yet durable materials, you can achieve substantial savings in production processes. This approach not only reduces initial expenses but also minimizes recurring costs, contributing to enhanced profitability.

- Maintain Product Integrity: It’s crucial to ensure that the chosen materials do not compromise product integrity. For instance, using recycled cardboard that is still strong enough to withstand transit stresses ensures your products reach customers in optimal condition.

- Customer Satisfaction: High-quality packaging materials enhance customer satisfaction by ensuring products arrive undamaged, reinforcing brand reliability and trustworthiness.

Efficient Manufacturing Models:

- Long-term Savings: By choosing low-cost yet durable materials, you can achieve substantial savings in production processes. This approach not only reduces initial expenses but also minimizes recurring costs, contributing to enhanced profitability.

- Maintain Product Integrity: It’s crucial to ensure that the chosen materials do not compromise product integrity. For instance, using recycled cardboard that is still strong enough to withstand transit stresses ensures your products reach customers in optimal condition.

- Customer Satisfaction: High-quality packaging materials enhance customer satisfaction by ensuring products arrive undamaged, reinforcing brand reliability and trustworthiness.

Efficient Manufacturing Models:

Incorporating efficient manufacturing models further optimizes material usage. Techniques such as:

- Customized Package Sizes: Tailoring package sizes to fit products precisely reduces excess material use and lowers dimensional weight charges during shipping.

- Packaging Design Optimization Techniques: Streamlining design processes to minimize material wastage without sacrificing aesthetic appeal or functionality. Companies like Arka and Pratt are great resources for designing cost effective packaging.

By integrating these strategies into your packaging processes, you strike a balance between cost and performance, ultimately leading to significant reductions in packaging expenses while maintaining high standards of product integrity and customer satisfaction.

4. Automating Fulfillment Processes For Faster Turnaround Times And Improved Accuracy Levels In Packing Operations

When selecting your packaging, it’s important to ensure it adheres to your automation goals. Automation in packing lines offers a multitude of benefits, including productivity gains, labor cost reductions, and consistency in achieving tight tolerances on package dimensions. In addition, Automated Storage and Retrieval Systems (AS/RS) can reduce picking errors and speed up fulfillment operations. This consistency is particularly crucial for meeting specific retailer guidelines, such as those required by Amazon.

Key Benefits of Automation:

- Productivity Gains: Automated systems can operate around the clock, significantly increasing the number of packages processed per hour. Unlike human labor, machines do not require breaks or shift changes, leading to more efficient operations.

- Labor Cost Reductions: By integrating automated packing technology, you can reduce the need for manual labor. This results in substantial cost savings, especially when considering long-term operational expenses.

- Consistency: Automated systems ensure that each package meets exact specifications. This level of consistency is essential for maintaining customer satisfaction and adhering to vendor requirements.

Examples of Automated Systems:

- Automated Guided Vehicles (AGVs): Used for transporting materials within the warehouse, reducing the need for manual handling.

- Conveyor Systems: Streamline the movement of packages through different stages of the fulfillment process.

- Automated Box Erectors and Sealers: Ensure that boxes are consistently erected and sealed according to required specifications.

By adopting these automated technologies, you not only save time but also maintain high levels of accuracy and efficiency across your packing operations. This approach aligns with cost-saving measures and strategies for packaging cost reduction, ensuring optimal performance without compromising on quality or customer satisfaction.

Adopting automation is a pivotal step towards packaging design optimization techniques and customized package sizes that meet industry standards while minimizing expenses.

Smart Shipping Practices That Can Help You Save On Transportation Costs Too!

Implementing smart shipping practices can significantly reduce your transportation costs and encourages on-time delivery. Some key strategies include:

- Utilize Regional Carriers: Opt for regional carriers who specialize in specific geographic areas, leveraging established relationships with local delivery partners to offer faster transit times and more competitive rates.

- Optimize Shipping Zones: By strategically placing fulfillment centers closer to your customer base, you can minimize shipping zones, thereby lowering shipping costs and ensuring quicker deliveries.

- Consolidate Shipments: Combining multiple orders into a single shipment can lead to substantial savings. This practice reduces the number of packages sent and leverages bulk shipping discounts.

- Negotiate Carrier Rates: Regularly review and negotiate rates with your carriers based on volume commitments and service level agreements. Taking advantage of these negotiations can lead to significant reductions in transportation expenses.

- Leverage Technology: Implement advanced shipping software that automatically selects the most cost-effective carrier and route for each shipment based on real-time data.

Incorporating these smart shipping practices will not only cut down on transportation expenses but also enhance overall operational efficiency, contributing positively to your profit margins.

Gain More Insight into Lowering Your Expenses

Maximizing your profit margins depends on effectively reducing packaging costs. You can achieve substantial savings without sacrificing quality by implementing the strategies discussed. Optimized package design, material selection, automation, and streamlined warehouse operations are critical areas to focus on.

Key Takeaways:

- Optimize Package Design: Reduce materials and transportation costs by refining size and shape.

- Choose Cost-Effective Materials: Balance cost with performance using sustainable options where feasible.

- Automate Processes: Increase efficiency and accuracy while lowering labor costs.

- Streamline Warehouse Operations: Improve lead times and overall supply chain efficiency.

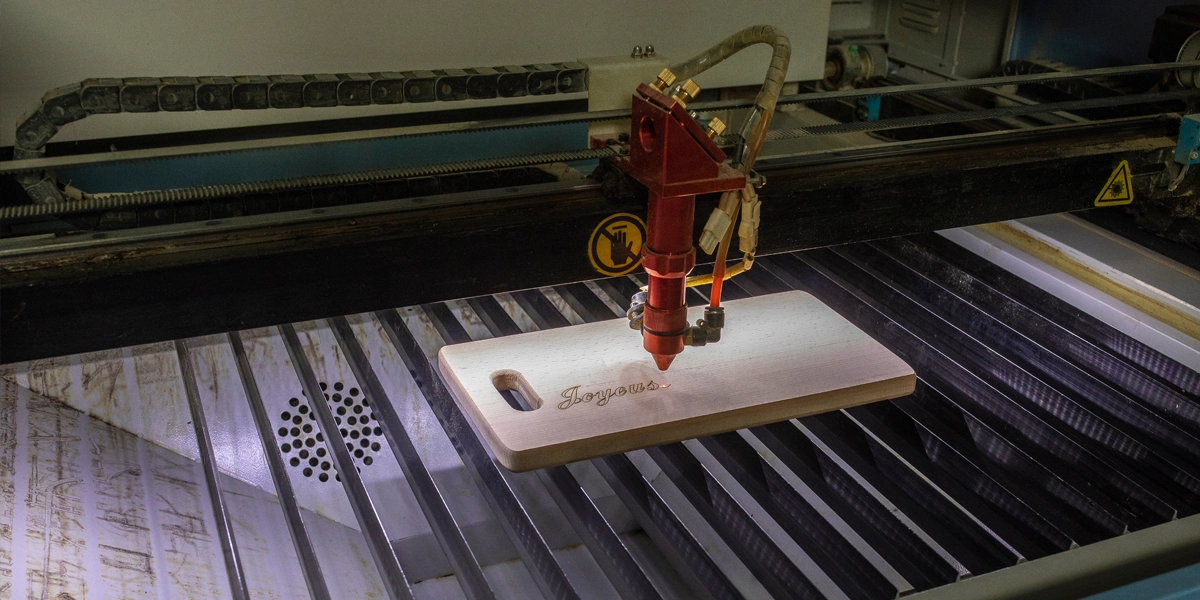

Working with One World Direct provides you with industry-leading solutions tailored to reduce packaging expenses. We offer a range of fulfillment services, including personalized-to-consumer fulfillment, which allows for ecommerce personalization, such as engraving and embroidery on products. Our expertise in D2C and B2B fulfillment ensures that your products are packaged efficiently and delivered on time, thrilling your customers while boosting your bottom line.

When you partner with One World Direct, you’re not just cutting costs—you’re optimizing every aspect of your fulfillment process. Let us help you unlock greater profitability through smarter packaging solutions. Book a meeting to learn more!

In This Article:

Subscribe to our Newsletter

Tincidunt urna mauris eu quam vulputate lobortis sit. Purus feugiat arcu nunc quisque massa ut.