In This Article:

There is a lot that happens in a warehouse, and a lot to focus on, but the number one thing to optimize for keeping warehousing costs down is your inbound receiving. The data you log upon receipt of goods affects everything else that happens down the line. Making sure it is accurate can have a huge impact on your bottom line.

EASY WINS

The first place to start optimizing your receiving is with your supplier. Have them separate skus to eliminate error-prone manual sorting upon receipt. Use a labeling system to standardize your process and reduce the chance of mistakes. Finally, have two employees perform a count independently, then check their results against each other.

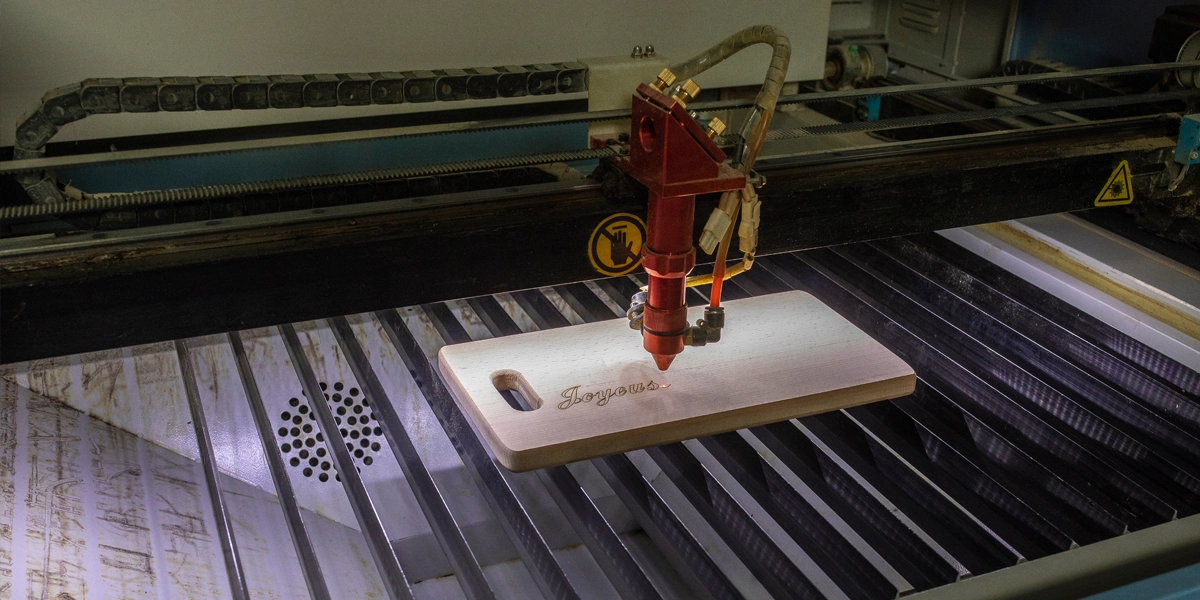

GETTING CREATIVE

Every e-commerce operation is different. To get next level results with your receiving, bring your team together to identify any pain points you have. Then get creative. Think of ways that are unique to your particular operation that can reduce your margin for error.

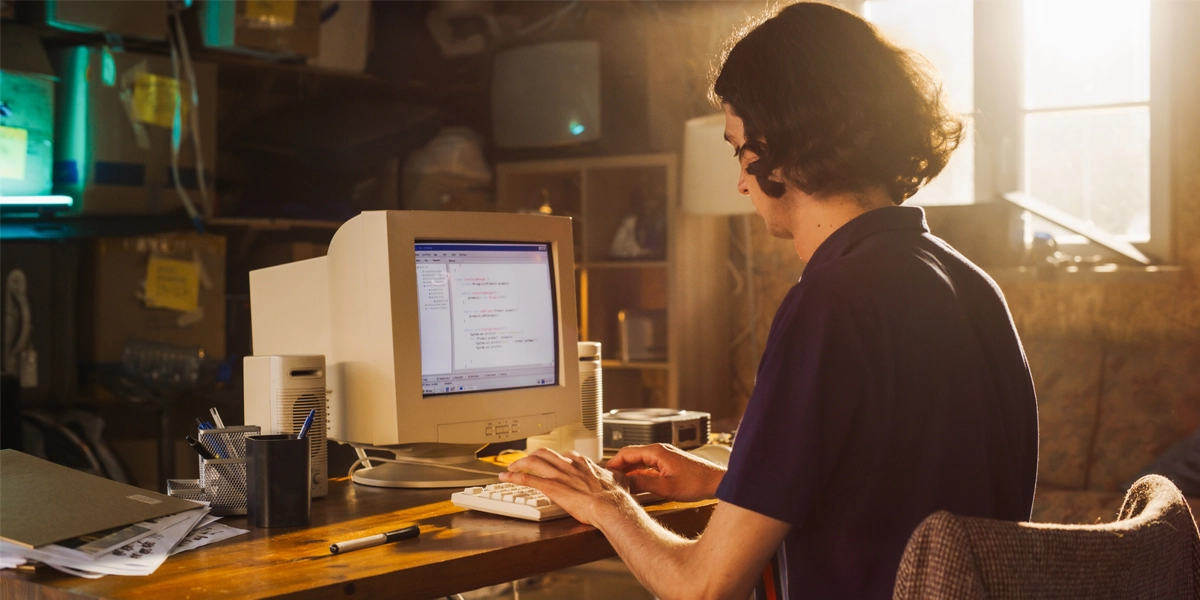

THE LIMITS OF SOFTWARE

While forecasting software is often touted as a solution for high warehousing costs, you need enough volume to justify the expense. And, software is only as good as the data it processes, so being rigorous with your receiving is still mandatory for getting the most out of your system.

If you’d like to talk more about the joys of warehouse management, give us a call! Or shoot us an email if that’s more your style. We can talk about this stuff all day. 1-866-289-9010. Or drop us a line at sales (at) owd (dot) com.

In This Article:

Subscribe to our Newsletter

Tincidunt urna mauris eu quam vulputate lobortis sit. Purus feugiat arcu nunc quisque massa ut.