In This Article:

Managing your ecommerce inventory is crucial for running a successful online store. It involves keeping track of products from when they’re purchased to when they’re sold, ensuring you have the right items available at the right time. Effective inventory management is key to smooth business operations and keeping customers happy.

Inventory management for many ecommerce brands quickly becomes a challenge, both from a technical and financial standpoint. Explore the top 7 challenges you may face when managing your ecommerce inventory and ways to improve your logistic operations. We’ll cover topics such as improving visibility, coordinating across multiple sales channels, and accurately predicting demand. For each challenge, we’ll provide practical solutions to help you optimize your processes and improve efficiency.

Discover the ins and outs of ecommerce inventory management and learn the advantages of partnering with an ecommerce fulfillment company to gain the infrastructure, tech, and team needed to deliver a flawless logistics experience.

1. Inventory Visibility for Ecommerce

Inventory visibility in ecommerce refers to having real-time information about stock levels and product locations throughout the supply chain. This transparency is crucial for smooth operations and can impact everything from order fulfillment to customer satisfaction.

Challenges without sufficient inventory visibility include:

- Delayed Response: When you don’t have up-to-date data, it’s difficult to restock quickly when demand is high, which can result in lost sales.

- Customer Dissatisfaction: Inaccurate stock information may lead to situations where you can’t fulfill orders, leading to disappointed customers and damaging your brand reputation.

- Inefficient Resource Allocation: Without knowing the status of your inventory, it’s challenging for teams to prioritize their efforts effectively.

Strategies for Enhanced Inventory Visibility:

- Implement Online Inventory Management Systems: These systems offer a centralized platform for tracking stock levels across different channels and warehouses. 3PLs use warehouse management systems (WMS) to oversee product coordination and inventory forecasting.

- Utilize Barcode Scanners: By using barcode scanners, you can ensure that every item is properly recorded, reducing errors and enabling accurate tracking.

We have our own tech stack of advanced inventory management tools to help our clients operate more flexibly and accurately. Whether you are a growing D2C brand or an omnichannel enterprise business, flawless ecommerce integrations are achievable with our transparent and cost-effective approach to ecommerce fulfillment services.

2. Handling Multiple Channels and Warehouses

Merchants often struggle to synchronize their various sales channels and manage inventory across multiple warehouse locations. Selling across various platforms and marketplaces amplifies exposure and introduces the challenges of synchronizing stock levels and ensuring prompt order fulfillment.

Key Challenges

- Disparate systems leading to inconsistent stock data

- Increased risk of overselling or stock discrepancies

- Coordination difficulties between multiple storage locations

Strategic Solutions for Inventory Synchronization

To navigate these challenges, consider these strategies:

1. Integrate POS Systems

Utilize point-of-sale (POS) syncing technology to ensure real-time inventory updates across all sales channels. This technology plays a pivotal role in maintaining accurate stock counts, averting the pitfalls of overselling.

2. Centralize Management

Deploy a centralized warehouse management system (WMS) that acts as a single source of truth for inventory across all warehouses. With such systems, you gain enhanced control over stock distribution, optimizing fulfillment routes based on proximity and availability.

3. Leverage Omnichannel Fulfillment Services

Partner with 3PLs offering omnichannel order fulfillment, such as One World Direct, to streamline operations. Such partnerships can significantly reduce the burden of managing multichannel logistics, letting you focus on sales and growth. We have integrations with any shopping cart, marketplace, OMS, or ERP. Our in-house tech team also handles custom integrations through our open API.

3. Overselling and Overstocking

Overselling and overstocking pose significant risks. While seemingly on opposite ends of the spectrum, both of these issues lead to customer dissatisfaction and potential financial losses.

Overselling occurs when you sell more products than you actually have in stock. This can lead to delayed deliveries, canceled orders, and a damaged brand reputation. On the other hand, overstocking refers to having excess inventory that isn’t selling. This ties up capital in non-moving goods and increases storage costs.

These problems highlight the critical importance of accurate demand forecasting. Getting it right involves predicting customer demand to optimize inventory levels effectively.

- Businesses can utilize advanced predictive analytics algorithms to analyze past sales data, identify trends, and forecast future demand.

- Use real-time inventory tracking to help prevent overselling by always knowing exactly what is in stock and available for sale. This real-time data helps maintain accurate inventory records, minimizing the risk of selling products that are no longer in stock.

- Maintain a buffer inventory and establish a safe stock level to help prevent both overstocking and stockouts by compensating for fluctuations in demand. This strategy involves calculating an optimal amount of extra inventory that should be maintained to cover unexpected spikes in sales without excessively tying up capital in unsold goods.

- Set up low inventory alerts within your WMS to help remind you when you need to order more inventory or send more products to your warehouse.

4. Lack of Data Insights

Effective inventory management relies on data insights. However, many ecommerce businesses struggle to access and analyze meaningful data about their inventory to guide their inventory decisions, drive growth, and ensure efficient operations.

The problem often arises from either not having the right tools and techniques for data collection or being overwhelmed by a large amount of data, which makes it difficult for businesses to know where to begin. This is where implementing a powerful inventory management software becomes crucial.

A software solution offering comprehensive reporting features can streamline the data analysis process. It can uncover valuable information about sales trends, customer behavior, product performance, and other important inventory management metrics. By utilizing these insights, you can confidently make decisions that align with your business goals and customer demands.

5. Demand Fluctuations

Many ecommerce brands see a challenge in managing inventory levels due to demand fluctuations. These are the natural ups and downs in customer demand that can greatly impact your inventory levels. Things like seasonal changes, shifts in market trends, or special promotions can cause them.

Understanding and predicting these changes is important so you can keep your inventory at the right level. If you don’t, you might end up with too much stock or not enough, and both can hurt your profits.

The Power of Sales Forecasting

One effective way to deal with demand fluctuations is through sales forecasting. This involves studying past sales data and market trends to make educated guesses about future sales patterns. For example, if your data shows that sales tend to spike during the holiday season, you can plan ahead by stocking up early.

The Role of Market Trends

Oversight of current market trends is another key factor in managing demand fluctuations. By staying connected to what’s happening in your industry, you can understand how customer preferences might change and adjust your inventory accordingly.

By incorporating these strategies into your inventory management process, you’ll be better equipped to handle demand fluctuations and ensure that you always have the right products available for your customers when they need them.

6. Reverse Logistics

Reverse logistics involves managing returned products, from receiving the items to reintegrating them into the stock or disposing of them. The challenges associated with reverse logistics can be daunting. For instance, processing returns may cause disruptions in inventory levels, while managing the reverse supply chain often involves additional costs and complexities.

To triumph over these challenges:

- Streamlining return policies is crucial. Clear guidelines on product returns help maintain customer satisfaction and facilitate efficient return processing.

- Leveraging automation tools can significantly ease the burden of managing returned items. Automated systems can track, sort, and reintegrate returned inventory, ensuring minimal disruption to your business operations.

- Use US-based call center services to handle customer returns via calls, email, or chats. An effective customer service team will carry the weight of guiding your customer through the returns process and ensure all returned items are within your set guidelines.

- Partnering with a 3PL that can process returns enables a smooth experience for you and your customer. A capable 3PL should be able to handle the entire returns process from receipt to restocking items that can be resold or donating damaged products. This includes inspection, refurbishing, rebagging and retagging, quarantined products, and so much more.

7. Stockouts

Stockouts are a major problem for any retailer, harming the customer experience and damaging your brand’s reputation. When you don’t have enough inventory to meet demand, it leads to lost sales and frustrated customers. Stockouts cost US and Canadian retailers an estimated $350 billion every year, but by using demand forecasting and the right tools, you’ll always have the stock you need to satisfy your shoppers.

Here are some strategies you can use to prevent stockouts:

- Employing real-time inventory tracking systems: These systems provide the most up-to-date information on your stock levels, allowing you to proactively restock and minimize the chances of unexpected shortages.

- Implementing just-in-time (JIT) inventory management practices: JIT approaches help you synchronize order production and delivery with actual demand, which in turn helps reduce excess stock and lowers the risk of stock outs.

- Unified commerce platform: Consolidate your entire ecommerce operation under a central platform to have the most accurate inventory data and avoid manual oversight of inventory levels from multiple systems.

- Demand forecasting using accurate reports: Inaccurate reporting can lead to forecasting issues. Review monthly reports to determine your most popular products and inform inventory purchase decisions.

Inventory Management has Never Been Easier than with OWD

Inventory management and fulfillment are huge challenges for independent online retailers. Investing in the infrastructure, technology, and team is often not feasible, so partnering with a reputable 3PL will improve your entire fulfillment operations and your bottom line.

OWD can handle all your fulfillment operations from improving inventory visibility to handling multiple sales channels, managing demand fluctuations, and addressing reverse logistics. Use our robust logistics tech stack to gain the data insights and predictive analytics you need to manage your inventory effectively.

Partner with us to lower your fulfillment costs and start offering two-day or even same-day shipping in the United States. We have three fulfillment centers strategically located across the country to suit any e-tailer’s needs.

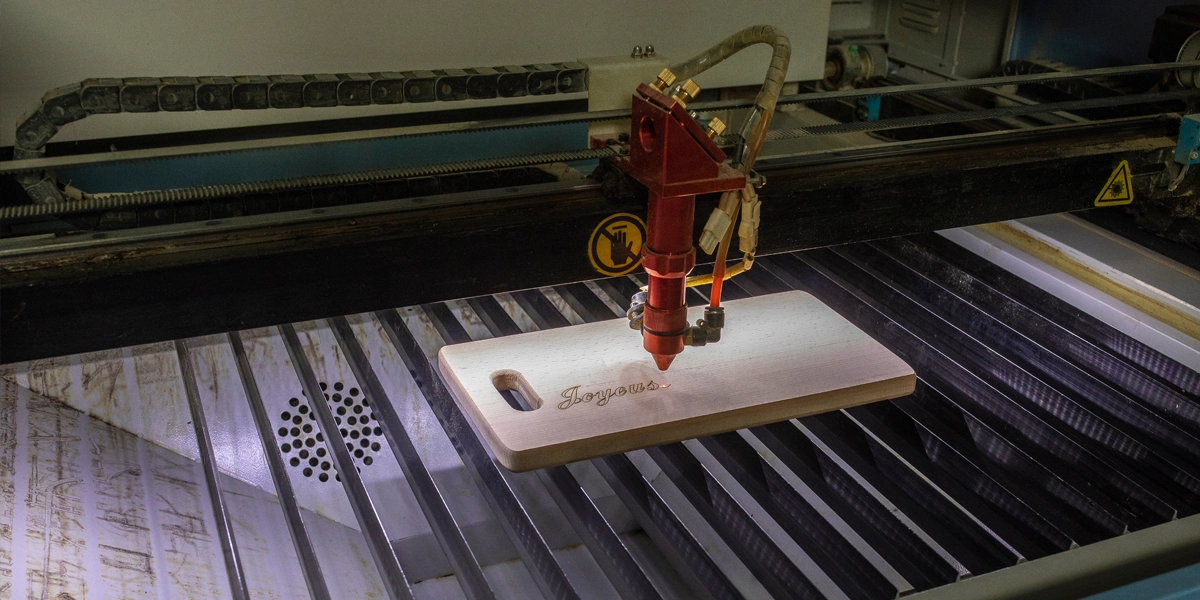

Best of all, you can begin to offer product personalization without any upfront investment on your end. We are the only 3PL that offers Personalized-to-Consumer Fulfillment (P2C), an innovative approach that allows you to offer engraving and embroidery on your products, as well as custom greeting cards at checkout.

Review your approach to inventory management with a professional fulfillment specialist during an initial consultation. Discover ways to improve your fulfillment approach, lower costs, and deliver a world-class ecommerce shopping experience.

In This Article:

Subscribe to our Newsletter

Tincidunt urna mauris eu quam vulputate lobortis sit. Purus feugiat arcu nunc quisque massa ut.