In This Article:

Ecommerce personalization is the biggest opportunity for online retailers in 2025. Product customization is in high demand and can radically increase revenue for struggling ecommerce brands. Consumers are willing to pay an average 25% premium for personalized or customized items, and 77% of consumers have chosen, recommended, or paid more for a brand that provides product personalization.

77%

of consumers have chosen, recommended, or paid more for a brand that provides product personalization.

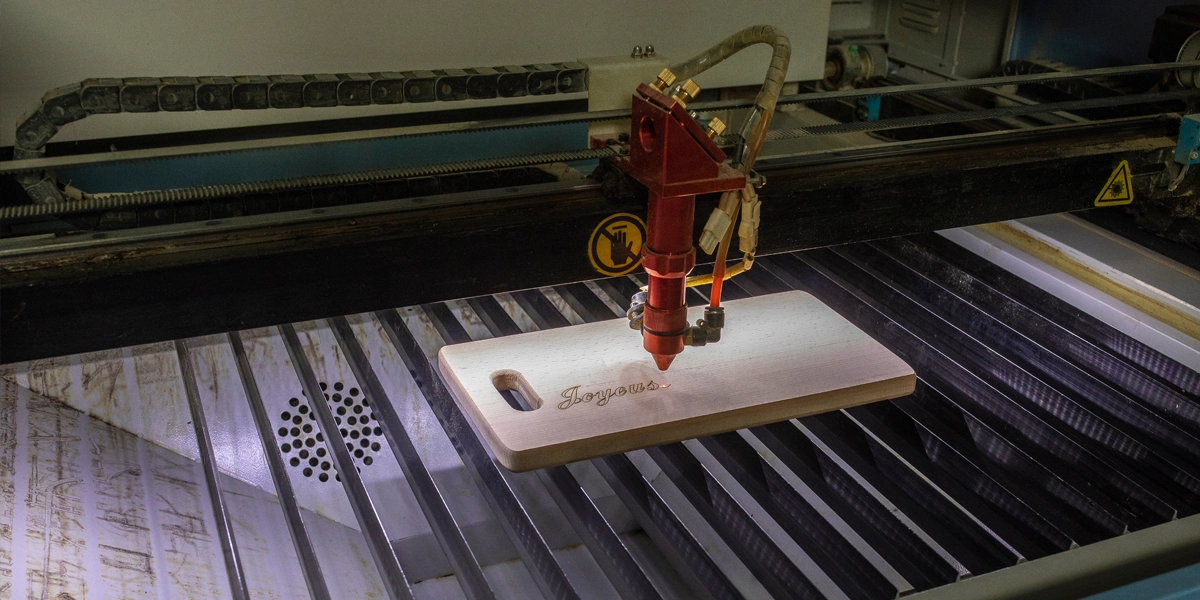

OWD is the only 3PL that offers product personalization as part of our fulfillment services. Personalized-to-Consumer (P2C) fulfillment allows for seamless product personalization. Shoppers can customize their products with engravings, embroidery, or direct-to-objecting printing to create luxury, artisanal, one-of-a-kind products. An often overlooked component of the personalization process is using jigs and fixtures, which are essential in ensuring precise and efficient personalization.

Jigs and fixtures are fundamental to the manufacturing process, acting as guides and supports that hold products in place during customization, helping to guarantee high-quality results while minimizing errors. Our Director of Personalization, Ryan Wheeler, gives his expert take on what you need to know to produce jigs and fixtures.

Key takeaway: Effective jigs and fixtures ensure that each product meets the highest standards of quality and consistency, thereby enhancing customer satisfaction. As businesses aim to deliver personalized products at scale, skilled technicians must create custom jigs and fixtures for each item to provide the best results.

Understanding Jigs and Fixtures

When exploring the mechanics of product personalization, it’s crucial to understand what jigs and fixtures are. Both play important roles in ensuring precision, especially when working on product customization.

Jigs

A jig is a custom-made tool used to control the location and motion of another tool. Essentially, it guides the cutting or shaping tool as it moves through its operational cycle. Jigs are crucial in processes where precision is key, such as drilling holes at exact locations on a product.

For instance, technicians would use a jig to engrave personalized messages on metal keychains. The jig securely holds the keychain while guiding the engraving laser to ensure each letter is etched perfectly.

Fixtures

On the other hand, fixtures are devices used to hold a workpiece firmly in place during machining operations. Unlike jigs, they do not guide the cutting tool but instead focus on ensuring the stability and precision of the workpiece itself.

A classic example would be a fixture used in embroidery machines for personalized clothing items; it keeps fabric taut and steady as the machine embroiders designs or monograms.

Jig vs Fixture: Key Differences

Aspect | Jigs | Fixtures |

|---|---|---|

Functionality: | Guide tools during processes like engraving or direct-to-object printing | Secure the workpiece in place for stability |

Role in Personalization: | Ensure accuracy by directing movement of tools | Maintain stability for techniques such as embroidery |

Mobility: | More mobile due to their guiding function | Typically stationary for precision and consistency |

Both jigs and fixtures are essential in manufacturing workflows aimed at personalization. They enable businesses to consistently deliver high-quality, customized products by minimizing errors and improving throughput.

Whether you’re engraving names on leather goods or embroidering designs onto apparel, having well-designed jigs and fixtures can make all the difference in achieving precise results every time.

The Importance of Jigs in Ensuring Accurate Personalization

Jigs: Essential Tools for Precision and Consistency

Jigs are essential tools that help achieve a high-quality finished product by guiding tools and components during the personalization process. Whether you’re engraving, embroidering, or printing directly onto objects, jigs ensure that everything stays aligned and repeatable, resulting in faster production and higher-quality parts.

How Jigs Boosts Efficient Personalization

- Engravings: For tasks like laser engraving, jigs hold items securely in place, ensuring the laser etches designs with exact precision. This prevents errors and allows for faster processing, as each piece is positioned correctly without manual adjustments.

- Embroidery: In embroidery processes, jigs ensure fabrics are taut and correctly aligned under the sewing machine. This precision results in uniform stitch patterns across multiple units, reducing waste and improving efficiency.

- Direct-to-Object Printing: When printing directly onto products such as mugs or bottles, jigs stabilize the item to allow for the consistent application of ink. This stability leads to high-quality prints that are free from smudging or misalignment.

Enhancing Production Speed and Part Quality

The use of jigs leads to noticeable improvements in production speed. By reducing setup times and manual interventions, businesses can speed up their personalization processes while still maintaining high standards of quality. Fewer mistakes also mean less rework and waste, which saves money and makes customers happier.

By incorporating well-designed jigs into your production line, you ensure that each personalized item meets the desired specifications quickly and accurately. Creating jigs requires skilled technicians and craftsmanship. The process involves trial and error, but high-level practitioners can find the right solution quickly. This strategic approach not only upholds brand integrity but also strengthens customer loyalty through consistently delivering superior personalized products.

Designing Effective Jigs for Different Product Types

Creating effective jigs is an art that combines technical precision with creative problem-solving, especially when dealing with various product types. Whether you’re working on curved surfaces or flat ones, the design process must be meticulous to ensure optimal results in product personalization. Let’s explore the nuances of designing jigs and fixtures for different product types.

Utilizing CAD Designs in Jig Development

Computer-Aided Design (CAD) software has changed how we create jigs and fixtures. Its accuracy and flexibility make it invaluable in developing designs tailored to specific product requirements. Here’s why CAD is vital:

- Precision and Accuracy: CAD software allows designers to draft jig designs with exact specifications, reducing errors that can occur in manual design processes.

- Visualization: With 3D modeling capabilities, CAD enables you to visualize how a jig will interact with the product, ensuring a perfect fit before any physical production begins.

- Customization: Rapid adjustments and customizations can be made quickly, accommodating changes in product design or personalization techniques.

Imagine wanting to engrave a complex pattern on a curved surface—CAD helps you simulate the engraving process, ensuring the jig holds the product at precisely the right angle for consistent results. This level of customization is crucial for efficient personalization.

Designing Jigs for Curved vs. Flat Surfaces

The challenge of designing jigs often lies in the surface type of the product:

For Curved Surfaces: | For Flat Surfaces: |

|---|---|

Considerations: Curved surfaces require jigs that can securely hold the product without damaging or distorting it. | Considerations: While seemingly straightforward, flat surfaces still demand precision. Misalignment can lead to poor personalization quality. |

Design Tips: Use flexible materials or adjustable components to accommodate the curvature of your jig design. CAD can simulate these interactions, allowing you to test different configurations virtually. | Design Tips: Ensure alignment features are incorporated into your jig design. CAD software helps by providing accurate measurements and alignment tools. |

Both surface types benefit from using CAD designs for creating detailed and accurate jigs, ensuring every personalized touch aligns perfectly with customer expectations.

Making Jigs & Fixtures for Efficient Personalization

Efficiency is key in personalization processes, where time and accuracy translate directly into customer satisfaction and business success. Effective jig design contributes significantly by streamlining workflows and minimizing errors:

- Reduction of Setup Time: Well-designed jigs reduce setup times between different personalization tasks, allowing more products to be personalized within shorter timeframes.

- Consistency Across Products: Standardized jigs ensure each product receives uniform treatment, maintaining high-quality standards across batches.

By leveraging CAD technology in your jig development process, you enhance accuracy and improve overall efficiency in your personalization efforts.

Material Selection for Jigs: Common Options and Their Benefits

Choosing the right material is a critical step in designing effective jigs and fixtures, especially when considering the personalized product’s shape or complexity. Whether you’re working on curved or flat surfaces, the material used can significantly affect the jig’s performance and longevity.

Common Materials Used in Jig Production:

- Aluminum: Lightweight, easy to machine, corrosion-resistant. Ideal for creating jigs that require frequent handling or need to be transported.

- Steel: Extremely durable, capable of withstanding heavy loads and high temperatures. Perfect for jigs that need to endure rigorous use over time.

- Plastics (e.g., ABS, Acrylic): Cost-effective and easy to mold into complex shapes. Suitable for less demanding applications where weight and cost are key considerations.

- Wood: Readily available, easy to work with, and environmentally friendly. Useful for prototyping or low-volume production runs.

Whether you’re personalizing items with intricate details or accommodating unique product shapes, selecting the appropriate material ensures your jigs perform optimally throughout their lifespan.

3D Printing Technology for Customized Jigs

The introduction of 3D printing technology has transformed how we create jigs and fixtures, particularly for personalized products. This additive manufacturing method provides the flexibility to design highly customized jigs that meet specific project needs.

Benefits of 3D Printed Jigs:

- Customization: 3D printing enables the production of jigs that are precisely shaped to fit the product being personalized. Intricate designs can be easily accommodated whether dealing with curved or flat surfaces.

- Rapid Prototyping: The ability to produce prototypes quickly allows for swift adjustments, ensuring efficient personalization processes. This is especially important when designing jigs for complex items or unique shapes.

- Cost-Effectiveness: Traditional methods of jig manufacturing can be expensive and time-consuming, but 3D printing reduces both production time and material waste, resulting in significant cost savings.

- Versatility in Material Use: A wide variety of materials can be used in 3D printing, each offering different advantages such as durability, flexibility, or lightweight properties. This versatility ensures that the jig meets the specific requirements of the personalization task.

When creating jigs and fixtures for products with different surface conditions—such as curved versus flat surfaces—a key factor to consider is the product’s shape. These CAD digital models serve as detailed blueprints that guide the 3D printing process, ensuring precision and accuracy in jig production.

By utilizing 3D printing technology, businesses can achieve greater efficiency in their personalization efforts. This innovative approach increases productivity and perfectly aligns with the goal of creating jigs and fixtures that enable efficient product customization.

Enhancing Production Efficiency with Well-Designed Jigs

Increasing throughput with jigs is a game-changer in the manufacturing and personalization process. Properly designed jigs streamline production workflows, significantly reduce errors, and boost productivity. Here’s how:

- Consistency and Precision: A well-crafted jig ensures that each product is positioned accurately for personalization, whether it’s engraving, embroidery, or printing. This precision eliminates the need for constant adjustments, leading to uniformity across all products.

- Error Reduction: By providing a stable and repeatable positioning mechanism, jigs minimize human error. Misalignments and repetitive mistakes are drastically reduced, which translates into less rework and waste.

- Time Efficiency: With the right jig in place, setup times are shortened. Operators can quickly secure items in the jig without measuring or positioning each piece individually. This efficiency allows more products to be processed in less time.

- Enhanced Workflow: Jigs facilitate a smooth flow in the production line. They allow operators to focus on core tasks rather than adjustments and corrections, creating an uninterrupted workflow that maximizes output.

- Cost Savings: Reduced error rates and increased speed contribute to lower operational costs. The initial investment in designing effective jigs pays off quickly as production scales up without a corresponding increase in labor costs.

Common Mistakes to Avoid When Designing Jigs for Personalization Projects

Creating effective jigs for personalization projects can be a game-changer, yet there are common mistakes brands make when designing jigs that can hinder their success. Recognizing these pitfalls is crucial to optimizing jig design and achieving superior results.

Typical Pitfalls in Jig Design

- Overlooking Material Properties: Choosing the wrong material can lead to durability issues or incompatibility with the products being personalized. It’s essential to match the material to the specific requirements of the personalization process.

- Inadequate Testing: Skipping or rushing through testing phases can result in jigs that don’t meet quality standards. This often leads to inconsistent personalization outcomes and increased waste.

- Complexity Over Practicality: Overly complicated jigs can be counterproductive, making setups more cumbersome and time-consuming rather than streamlining workflows.

- Ignoring Ergonomics: Poor ergonomic design affects user comfort and efficiency, potentially leading to higher error rates and decreased productivity.

Tips for Optimizing Jig Design

- Prioritize Material Selection: Analyze the specific needs of your project and select materials that provide the necessary strength, flexibility, and compatibility.

- Implement Rigorous Testing: Establish a thorough testing protocol to ensure each jig meets all performance criteria before full-scale production begins.

- Simplify Design Where Possible: Focus on simplicity without compromising functionality. A streamlined design can enhance efficiency and ease of use.

- Consider User Ergonomics: Design with the end-user in mind. Ensure that jigs are comfortable to use over extended periods and do not contribute to fatigue or errors.

By recognizing these common mistakes and applying practical solutions, businesses can enhance their jig designs, resulting in better personalization outcomes.

Rapid Prototyping with 3D Printed Jigs: A Game Changer in Jig Manufacturing

Rapid prototyping with 3D printed jigs has become a game changer in the world of product personalization. This new way of making jigs and fixtures offers many advantages, ultimately transforming how businesses get ready for personalization tasks.

Benefits of Rapid Prototyping in Jig Creation

Speed & Efficiency

Rapid prototyping allows for the quick creation of jig and fixture tooling, reducing lead times significantly. This agility is crucial for businesses aiming to respond promptly to market demands.

Customization

With 3D printing, each jig can be tailored precisely to the product specifications, ensuring efficient personalization and enhancing product quality.

Cost-Effectiveness

By minimizing material waste and enabling iterative testing, 3D printed fixtures offer a cost-efficient solution compared to traditional methods.

Overview of 3D Printing Technologies

Understanding different additive manufacturing technologies is key to leveraging their full potential:

- Fused Deposition Modeling (FDM): Ideal for creating durable and robust jigs at a relatively low cost.

- Selective Laser Sintering (SLS): Offers greater flexibility with complex geometries and is suitable for high-strength requirements.

- Stereolithography (SLA): Provides high detail resolution for intricate designs, making it perfect for precision-driven personalization.

Comparing Traditional Techniques vs. Modern Additive Manufacturing Approaches

Traditional jig manufacturing often involves labor-intensive processes like CNC machining, which can be costly and time-consuming. In contrast, modern additive manufacturing enables:

- Simplification of Complex Designs: 3D printing can handle intricate shapes effortlessly without additional costs.

- Iterative Design Improvements: Prototyping multiple iterations quickly helps in refining designs before final production.

This shift toward rapid prototyping improves how jigs are made and raises the bar for personalized product offerings. By embracing these advancements, businesses can stay ahead of the curve in innovation when it comes to creating efficient jigs and fixtures for personalization.

Leave Creating Jigs and Fixtures to the Pros

Invest in product personalization before you get taken out by a competitor who does. Explore One World Direct’s Personalized-to-Consumer (P2C) services. With features like engraving, embroidery, and custom greeting cards, OWD offers a seamless way to integrate personalization into your offerings without added costs. This is not just a service; it’s an opportunity to transform your fulfillment process into a profit center.

Ready to elevate your brand with efficient personalization? Book a consultation with our team today. We’ll take a look at your current approach to fulfillment and show you how we can help elevate your entire logistics process. Use our call center services for superior ecommerce customer support. Leverage our network of fulfillment centers and reach 99% of domestic shoppers in two days! Most importantly, discover how P2C can transform your business with seamless product personalization. We look forward to chatting with you soon!

FAQs (Frequently Asked Questions)

What are jigs and fixtures in manufacturing?

Jigs and fixtures are specialized tools used in manufacturing to hold, support, and guide the workpiece during production. Jigs are designed to control the location and motion of tools, while fixtures secure the workpiece in place. Together, they enhance accuracy and efficiency in processes such as personalization.

How do jigs contribute to effective personalization of products?

Jigs play a crucial role in achieving precise and consistent results during product personalization. They facilitate various techniques such as engravings, embroidery, and direct-to-object printing by ensuring that each item is accurately positioned for customization, leading to higher quality outcomes.

What is the difference between a jig and a fixture?

The primary difference between a jig and a fixture lies in their functions: a jig guides the tool's movement while performing operations on the workpiece, whereas a fixture primarily holds the workpiece securely in place without guiding any tools. Both are essential for efficient manufacturing processes.

How can CAD software improve jig design?

Computer-aided design (CAD) software allows for detailed and accurate jig designs by enabling manufacturers to create 3D models that can be easily modified. This technology enhances precision in jig development, making it easier to tailor designs for specific product types or complexities.

What common mistakes should be avoided when designing jigs for personalization projects?

Common mistakes include failing to consider product shape or complexity, neglecting material selection, and not testing prototypes adequately. To optimize jig design for better outcomes, businesses should focus on thorough planning, material compatibility, and iterative testing.

How does 3D printing technology benefit jig manufacturing?

3D printing technology allows for rapid prototyping of jigs, enabling manufacturers to create highly customized solutions that meet specific project requirements quickly. This additive manufacturing approach reduces lead times compared to traditional methods and allows for more complex designs that enhance production efficiency.

In This Article:

Subscribe to our Newsletter

Tincidunt urna mauris eu quam vulputate lobortis sit. Purus feugiat arcu nunc quisque massa ut.