In This Article:

Direct-to-object (D2O) printing is revolutionizing ecommerce. Brands can offer seamless product personalization and print directly onto three-dimensional objects. Unlike traditional methods that often require labels or secondary packaging, this technology allows for high-quality, customizable designs on a variety of surfaces, from drinkware to T-shirts.

This ultimate guide for 2024 will cover everything businesses need to know about leveraging direct-to-object printing in their fulfillment process:

- Detailed exploration of D2O Printing Technology

- Step-by-step guide on how the process works

- Comparison of different types of printing machines

- Real-life applications and success stories across industries

- Advantages of using our Direct to Object Printing services

Whether you’re a D2C brand looking for unique personalization options or a B2B company aiming to streamline operations, this comprehensive guide will arm you with the information you need to start D2O printing for your ecommerce business.

If you’re interested in learning more about other fulfillment services or how a 3PL works, we have resources to help you dive deeper and learn how to improve your ecommerce operations. It’s time to embrace the future of ecommerce fulfillment with direct-to-object printing and other personalized-to-consumer fulfillment services.

Understanding the Technology Behind Direct-to-Object Printing

Direct-to-object printing allows printing directly on various surfaces without the need for traditional mediums like paper or fabric. This innovative technology opens up new possibilities for customization and branding in packaging, promotional products, and manufacturing industries.

UV Inkjet-Printing Technology

One of the key technologies driving the growth of direct-to-object printing is UV inkjet printing. This technique utilizes ultraviolet (UV) light to instantly dry or cure the ink as it is applied to the object’s surface. Unlike traditional printing methods that rely on air drying or heat, UV inkjet printing offers several advantages:

- Instant Curing: UV light solidifies the ink instantly, reducing smudging and enabling high-speed printing.

- Versatility: Capable of printing on diverse materials without requiring pre-treatment, such as plastics, glass, metals, and even wood.

- Environmentally Friendly: UV inks are free from volatile organic compounds (VOCs), making them safer for both operators and the environment.

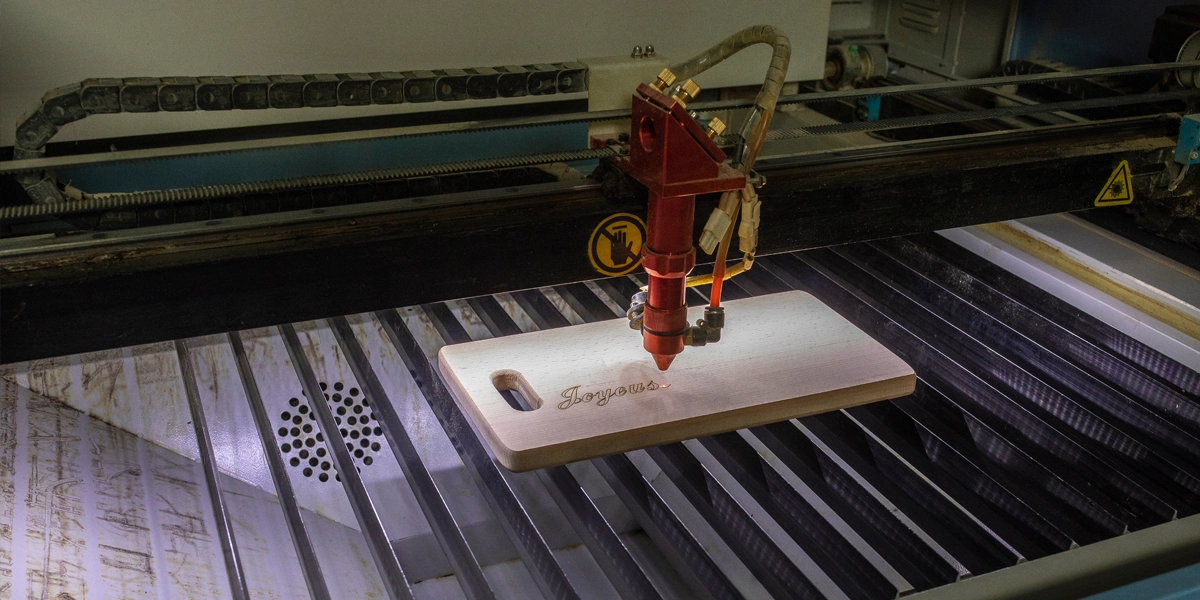

How Direct-to-Object Printing Works

Direct-to-object printing is a seamless process that integrates advanced technology with straightforward operational steps. As part of our P2C fulfillment services, we handle the entire process from start to finish. Here’s a step-by-step guide:

- File Preparation: Create or adjust your design using graphic software.

- Ensure the file is in a compatible format (e.g., JPEG, PNG, PDF).

- Adjust color profiles and resolution for optimal print quality.

- Object Placement: Place the object on the printer bed or cylindrical holder.

- Secure it properly to avoid movement during printing.

- Printer Setup: Load the prepared file into the printer’s software interface.

- Select appropriate settings (print speed, resolution).

- Printing Process: The printer head moves across the object, depositing UV ink.

- UV lamps cure the ink instantly as it’s applied.

- Post-Processing: Inspect the print for any imperfections.

- Perform additional curing if necessary.

Advantages Over Traditional Methods

Direct-to-object printing offers significant benefits compared to traditional printing methods like screen printing and pad printing:

- Customization: Easily print unique designs on each item without setup changes.

- Efficiency: Reduces production time by eliminating several steps involved in conventional methods.

- Quality: Achieves superior image resolution and color vibrancy with minimal fading over time.

Traditional methods often require extensive setup and are limited in terms of design complexity. In contrast, D2O printing excels in producing intricate patterns and gradients with precision.

Different Types of Direct-to-Object Printing Machines

D2O printing machines come in various types, each with its own features and benefits. Here, we’ll explore the two main categories: flatbed printers and cylindrical printers.

Flatbed Printers

Flatbed printers are versatile and efficient, designed to print directly onto flat surfaces:

Key Features:

- High Precision: Known for their ability to produce detailed and precise prints.

- Versatility: Capable of printing on various materials including plastics, metals, glass, and wood.

- Size Flexibility: Suitable for both small and large objects.

Ideal For:

- Ecommerce brands focusing on custom flat products like phone cases, signage, and promotional items.

- Industrial applications requiring durable and high-quality prints.

Pros:

- High Resolution: Delivers sharp and vibrant images.

- Material Versatility: Supports a wide range of substrates.

- Ease of Use: User-friendly interfaces streamline the printing process.

Cons:

- Space Requirements: Typically larger in size, requiring more space.

- Initial Cost: Higher upfront investment compared to some traditional printers.

Cylindrical Printers

Cylindrical printers specialize in printing directly onto round or cylindrical objects:

Key Features:

- 360-Degree Printing: Capable of wrapping designs around the entire surface of an object.

- Adaptability: Suitable for various cylindrical shapes like bottles, tumblers, and tubes.

- Precision Alignment: Ensures accurate placement of designs on curved surfaces.

Ideal For:

- Drinkware industry producing customized bottles, mugs, and jars.

- Manufacturers seeking branding opportunities on cylindrical packaging.

Pros:

- Comprehensive Coverage: Prints seamlessly around cylindrical items.

- Speed Efficiency: Faster production times for high-volume orders.

- Durability: Produces long-lasting prints resistant to wear and tear.

Cons:

- Limited Application Scope: Primarily restricted to cylindrical objects.

- Learning Curve: Requires specialized knowledge for optimal operation.

Key Considerations in Choosing the Right Printer

When deciding on a D2O printer, it’s important to take into account your specific fulfillment needs. Here are some key factors to consider:

- Product Range: Evaluate the types of products you plan to customize. Flatbed printers offer versatility across various shapes and materials, while cylindrical printers excel in round object customization.

- Production Volume: Higher volume production may benefit from the speed efficiency of cylindrical printers.

- Print Quality: Ensure the chosen printer meets your required resolution standards. Flatbed printers often provide higher resolution for intricate designs.

- Space Availability: Consider the physical footprint of each printer type relative to your available workspace.

Both types of machines require a hefty upfront investment and a skilled team to use the equipment, not to mention the space to store your printer. OWD can help you start to offer D2O printing using our personalized-to-consumer fulfillment services. Customers can personalize products with embroidery, engravings, and D2O imagery. We store, print, and ship your orders at a fraction of the cost of trying to do it on your own.

Learn more about the benefits of ecommerce personalization and explore some of our favorite examples to help you get inspired. And, if you’re looking for a new fulfillment partner, check out our guide on selecting a reliable 3PL provider or learn how ecommerce product customization can transform your business.

The Advantages of Choosing Our Direct-to-Object Printing Services

Choosing our D2O printing services offers many benefits that can improve your ecommerce operations. It’s just part of our P2C fulfillment services offering which sets us apart from other 3PLs.

Unique Selling Points

- Personalization at Scale

Our D2O printing capabilities enable you to personalize ecommerce products in ways that were impossible before. Whether you want to add custom logos, unique designs, or personalized messages, we can ensure high-quality prints on a wide range of materials.

- Boost Customer Engagement: Personalized products create an emotional connection with customers, increasing brand loyalty and repeat purchases.

- Expand Product Offerings: Introduce limited editions, seasonal items, and exclusive collections without significant lead times or setup costs.

- Personalized Products = Lower Returns: Customized products not only increase average order values but also have lower return rates than regular inventory.

- Streamlined Operations

Getting rid of labels and secondary packaging can greatly improve how efficiently you fulfill orders. With our D2O printing services, you can print directly on the object, reducing waste and simplifying your packaging process.

- Eco-Friendly Solution: By eliminating labels and secondary packaging, you contribute to a more sustainable fulfillment operation.

- Cost Savings: Reduce the material and labor costs associated with applying labels and additional packaging steps.

How We Help

1. Efficiency and Speed

Our state-of-the-art infrastructure ensures quick turnaround times without compromising quality. Ship personalized products to your customers faster using our expertise and state-of-the-art machinery. We can also help you overcome other challenges in inventory management and improve warehouse picking speed and accuracy using our extensive fulfillment systems and network for maximum customer satisfaction.

2. Versatility Across Products

Our printing technology adapts seamlessly across various objects, including apparel, phone cases, mugs, pet products, and glassware. Learn more about the possibilities during a complimentary logistics consultation. We’ll discuss how you can begin offering D2O printing and product personalization. We’ll also dive into how a partnership can reduce logistics costs while you can start offering fast two-day or oven overnight shipping.

3. Seamless Integration

We integrate seamlessly with over 200 ecommerce platforms through our open API. Our team can help you incorporate D2O printing into your existing workflow without replatforming or investing in new ecommerce software.

4. Client Support

We offer dedicated account managers so you have expert support to manage your fulfillment operations. We also offer call center services to handle your customer support via chat, email, and phone using only US-based agents.

Our commitment is not just about fulfilling orders; it’s elevating your business with the best ecommerce experiences for your shoppers. We empower your brand to stand out in the competitive ecommerce landscape by focusing on efficiency, sustainability, and unmatched personalization options.

Staying Ahead with Future Trends and Innovations in Direct-to-Object Printing

Future trends in D2O printing are set to revolutionize the industry. Emerging technologies, particularly advanced UV-LED systems, and innovative printhead designs are at the forefront of this transformation.

Advanced UV-LED Systems

UV-LED systems are a game-changer. Offering enhanced print quality and durability, these systems surpass traditional UV curing methods in several ways:

- Energy Efficiency: UV-LED lamps consume less energy compared to conventional mercury vapor lamps, reducing operational costs.

- Longer Lifespan: With a longer operational life, UV-LED systems require less frequent replacements, minimizing downtime.

- Instant On/Off: Unlike traditional lamps that need time to warm up, UV-LEDs can be turned on and off instantly, improving workflow efficiency.

These benefits make UV-LED systems an essential component for businesses aiming to stay ahead in the competitive ecommerce landscape.

Innovative Printhead Technologies

Innovative printhead technologies are another critical factor driving the future of direct-to-object printing. These advancements offer significant improvements in speed, precision, and versatility:

- Micro-Piezo Technology: This technology allows for precise droplet control, resulting in higher-resolution prints and finer details.

- Thermal Inkjet Printheads: Known for their speed and reliability, thermal inkjet printheads are ideal for high-volume printing tasks.

- Continuous Inkjet (CIJ) Systems: CIJ systems provide a continuous flow of ink, making them perfect for printing on irregular or curved surfaces.

These cutting-edge printhead technologies enable businesses to achieve unparalleled print quality across various materials and product shapes.

Why These Innovations Matter

Adopting these advanced technologies improves print quality and enhances operational efficiency. For example:

- Faster Turnaround Times: With quicker setup and curing times, businesses can fulfill orders more rapidly.

- Lower Operational Costs: Energy-efficient UV-LED systems reduce electricity consumption and maintenance expenses.

- Greater Customization: Advanced printheads allow for intricate designs and personalized touches that cater to consumer preferences.

Choosing the Right Partner for Your Direct-to-Object Printing Journey

1. Expertise and Experience

- Look for providers with extensive experience in UV Inkjet-Printing Technology.

- Evaluate their track record with various industries and product types.

- Ensure they offer comprehensive support from file preparation to ink curing.

2. Technology and Infrastructure

- Choose companies that utilize advanced printing technologies like UV-LED Systems.

- Ensure they have state-of-the-art printhead technologies for superior print quality.

- Verify their ability to handle large volumes without compromising on speed or quality.

3. Customization Capabilities

- Assess their ability to offer personalized solutions tailored to your specific needs.

- Check if they provide value-added services such as custom unboxing, greeting cards, or returns handling.

4. Customer Service and Support

- Opt for providers with robust customer support systems, including account managers and contact centers.

- Confirm their availability across various channels like chat, email, and phone.

Our Expertise Sets Us Apart

- Comprehensive Solutions: From basic fulfillment services to omnichannel strategies, we cover all aspects of ecommerce fulfillment.

- Personalization Options: With our free plug-in integration, clients can easily offer embroidery, engraving, D2O printing, or custom greeting cards at checkout.

- Global Reach: Our three fulfillment centers ensure 99% of the U.S. is reached within two days with ground shipping and we also provide fast shipment for your international shoppers. We help you compete with big retail capabilities and provide the best alternative to Amazon Prime.

- Exceptional Customer Support: We provide support for all your customer inquiries through our call center services.

Our commitment to innovation and customer satisfaction has positioned us as the preferred partner for businesses seeking top-notch D2O printing solutions.

Direct-to-Object Printing Made Easy

Offering D2O printing services for your product line is a great way to convert more shoppers and increase average order values. As part of our P2C fulfillment services, you can begin offering D2O printing without any hefty investment on your end.

Schedule a logistics consultation and our fulfillment experts will review your current processes and find ways to lower your fulfillment expenses while increasing service levels. By embracing our P2C service integration, you can unlock a multitude of benefits, including:

- Unmatched Personalization: Craft one-of-a-kind products that establish genuine connections with customers.

- Operational Efficiency: Streamline processes by eliminating excess labels and packaging.

- Enhanced Customer Experience: Delight customers with unique unboxing moments that foster loyalty.

Since 1994, our ecommerce fulfillment company has helped push the industry forward with superior logistics services for D2C and B2B businesses. Schedule a call, and we can game-plan an effective strategy to improve your entire fulfillment operations so you can focus on growing your business.

In This Article:

Subscribe to our Newsletter

Tincidunt urna mauris eu quam vulputate lobortis sit. Purus feugiat arcu nunc quisque massa ut.