In This Article:

Prioritizing ecommerce cost optimization will help turn a business from surviving to thriving. It’s about fine-tuning operations to get the most value out of every dollar spent, making sure that every part of the business runs efficiently.

Ecommerce cost optimization is not just about cutting expenses; it’s about using resources wisely to improve customer value and strengthen market position. As costs go up, from finding products to delivering them, businesses need to find ways to reduce operating costs while staying competitive.

Understanding how serious these challenges are, businesses need to use every tool they have available. Leverage smart call center services to enhance customer satisfaction by letting an outside specialist handle calls, chats, and emails. You can also take advantage of comprehensive fulfillment services that streamline operations by providing direct-to-consumer, business-to-business, and personalized-to-consumer order fulfillment services.

It’s time to discover the most practical ways to reduce logistics and warehousing costs while still delivering superior fulfillment experiences that meet your customers’ high expectations.

The Key Costs in Ecommerce

Understanding the costs involved in running an online business is crucial for success in the world of ecommerce. By having maximum transparency of all your expenses, you can take proactive steps to manage them effectively, maximize profitability, and stay ahead of your competition.

Inventory Costs: Capital and Storage Implications

- Capital Allocation: Inventory costs require a substantial amount of money from ecommerce businesses. This ties up capital that could otherwise be used for other important growth initiatives, such as marketing or investment in new software to improve your customer experience.

- Storage Constraints: Storing inventory takes up valuable space in warehouses, which comes with its own set of costs. These expenses can increase when there is excess stock or slow-moving items that aren’t selling well.

- Strategic Stocking: Finding the right balance between having enough stock to meet customer demand and not tying up too many resources is crucial. Efficient inventory management plays a key role in achieving this balance.

Inventory Management Tip: Analyzing how quickly inventory is being sold and implementing strategies like just-in-time (JIT) ordering can help optimize stock levels and free up capital. Learn more about common challenges in inventory management and how you can overcome them.

Return Costs: Impact on Profitability

- Eroding Margins: Returns are a natural part of ecommerce, but they can eat into your profit margins if not handled efficiently. The costs associated with processing returns, restocking items, and potential damage or loss can add up quickly.

- Streamlined Returns: Having a smooth and hassle-free returns process is crucial for minimizing the financial impact of returns while keeping your customers satisfied.

An easy way to reduce return rates is by providing detailed product descriptions, accurate sizing information, and high-quality imagery to ensure customers have a clear understanding of what they are buying. Check out our complete guide on the best strategies to reduce return rates for your business to maintain maximum profitability.

Packaging and Handling Charges: Dual Role in Experience and Expense

- Customer First Impressions: How you package your products significantly shapes customers’ first impressions of your brand. It can enhance their unboxing experience and create a perception of higher value.

- Logistical Considerations: Packaging choices also impact the cost of shipping. Factors like the packaging materials and the package size and weight can affect shipping rates. Custom brand packaging will also drive up fulfillment costs.

Optimizing packaging design to be both visually appealing and efficient can help reduce handling charges while improving the overall customer experience.

Labor Costs: The Human Element in Fulfillment

- Direct Influence: The people involved in fulfilling orders, such as warehouse staff and delivery personnel, have a direct impact on how efficiently orders are processed and shipped.

- Productivity Equals Profitability: Investing in training for your workforce and using technologies that automate or streamline certain tasks can lead to higher productivity. This, in turn, can help lower your labor costs per order.

- Strategic Staffing: Properly aligning staffing levels with order volumes can prevent overstaffing during slow periods and understaffing during peak seasons. Consider utilizing temporary or seasonal workers to meet increased demand without incurring significant

- Speed + Accuracy: Mistakes or delays in processing orders can result in additional labor hours spent on resolving issues, rework, or customer service. Implementing quality control measures and efficient order management systems can help minimize errors and ensure timely shipping. Check out our guides on how to reduce picking and packaging errors and how to improve warehouse picking speed and accuracy.

Strategies for Cost Optimization in Warehousing

Efficient warehouse management is crucial for minimizing ecommerce expenses. Implementing cost-saving strategies can directly increase profit margins. Here are some targeted approaches to reduce costs without compromising service quality.

1. Optimizing Outbound Processes

The first area to focus on is improving outbound processes within the warehouse. By making these processes more efficient, businesses can:

- Ensure faster and more accurate delivery of products to customers

- Reduce the amount of time products are held in the warehouse

- Lower overall operating costs

Here are some actionable steps to optimize outbound processes:

- Implement Batch Picking: Combine multiple orders into a single batch to minimize the number of trips needed around the warehouse.

- Utilize Order Sequencing: Process outbound orders based on delivery routes or pickup times to streamline fulfillment.

- Establish Quality Control Points: Check orders at strategic points in the outbound process to catch any errors before they reach the customer.

These measures not only improve workflow efficiency but also enhance customer satisfaction by ensuring timely and accurate deliveries.

2. Reducing Reverse Logistics Costs

Returns are a common occurrence in ecommerce, but they can be costly for businesses if not managed effectively. Implementing efficient returns management practices can significantly reduce reverse logistics costs. Here’s what businesses can do:

- Refine the Returns Policy: Clearly communicate guidelines to customers, which can help reduce unnecessary returns.

- Analyze Return Data: Look for patterns or recurring issues that may be causing a high number of returns and take corrective actions.

- Integrate a Robust Returns Management System that automates and streamlines the process for efficiency.

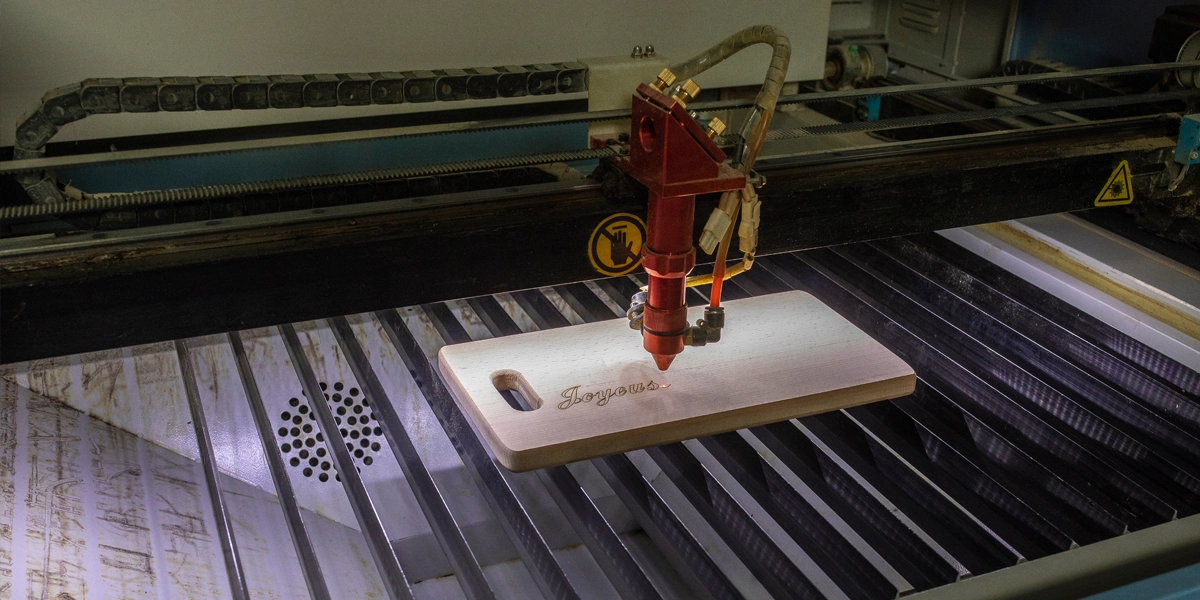

3. Leveraging Smart Automation Technologies

Incorporating automation technologies into your logistics operations is essential for cost optimization. These technologies can improve operational efficiency and accuracy, which translates to lower logistics expenses. Here are some examples of smart automation in warehousing:

- Automated Storage and Retrieval Systems (AS/RS): These systems use robots or conveyors to retrieve items from storage locations, reducing the need for manual labor and improving picking efficiency.

- Warehouse Management Software (WMS): Advanced WMS can optimize storage layouts, track inventory levels in real time, and assist with demand forecasting.

- Robotic Process Automation (RPA): RPA tools can handle repetitive tasks such as data entry or order processing, freeing up staff to focus on more complex work.

Optimizing warehousing operations is crucial for minimizing overall ecommerce costs. By focusing on improving outbound processes, reducing reverse logistics costs, and leveraging smart automation technologies, businesses can position themselves for sustainable growth and continuously find new ways to lower logistics expenses.

How to Reduce Transportation Costs in Logistics Operations

Transportation costs in logistics can be a significant part of the overall expenses for an ecommerce business. As fuel prices continue to change and consumer demands evolve, optimizing these costs becomes not just beneficial but essential for staying competitive. Here’s how businesses can tackle transportation expenses directly:

Analyze Carrier Cost Factors

Businesses must closely examine various cost factors that affect transportation expenses. Fuel prices and distance covered are two crucial components. By thoroughly analyzing these factors, businesses can choose carriers that offer the best rates for their shipping needs without compromising on delivery quality. Strategic carrier selection can involve:

- Comparison of Carrier Rates: Regularly compare rates from different carriers and negotiate better terms based on volume and loyalty.

- Zone Skipping: Ship goods in bulk to a closer zone before distributing them individually, reducing per-package shipping costs.

- Multi-Carrier Rate Shopping: Use software solutions that compare real-time rates across carriers, ensuring cost-effective choices for each shipment.

Implement Sustainable Packaging Tactics

Reducing shipping volume and the dimensional weight of packages cuts down on materials and transportation costs. Businesses should re-evaluate their packaging process to identify areas for improvement:

- Dimensional Weight Pricing: Understand how carriers price based on package volume and optimize packaging to align with the most economical dimensional weight brackets.

- Eco-Friendly Materials: Utilize recyclable, lighter-weight materials that maintain package integrity with less bulk.

- Custom Packaging Solutions: Design packaging that fits products snugly to avoid unnecessary space that increases dimensional weight charges.

Explore more sustainable logistics strategies with our ultimate eco-friendly fulfillment strategies guide.

Exploit Load Optimization

Efficiently loading cargo ensures maximum utilization of space within transportation vehicles, which translates to fewer trips and reduced costs.

- Consolidation of Shipments: Combine multiple smaller shipments into one larger shipment to utilize space more effectively and lower freight charges.

- Container Utilization Techniques: Employ tactics such as pallet optimization and multi-depth box designs that maximize container space usage.

Leverage Technology for Route Optimization

Advanced routing algorithms can significantly decrease miles driven, leading to lower fuel consumption and maintenance costs.

- GPS Tracking & Route Planning: Implement systems that provide real-time data on traffic conditions, enabling drivers to avoid delays and take the shortest possible routes.

- Driver Performance Analysis: Monitor driver habits to encourage fuel-efficient driving techniques. Use hybrid or electric trucks to lower emissions.

Explore more ways to optimize for first-mile and last-mile delivery to lower fulfillment expenses, improve your customer experience, and meet your on-time guarantees.

Optimize Shipping Strategies

Refine shipping strategies by considering distribution center locations relative to customer bases, thus minimizing distance traveled.

- Strategic Warehouse Placement: Position fulfillment centers closer to key markets, which can reduce transit times and shipping costs. One World Direct has three fulfillment center locations strategically placed in California, South Dakota, and Ohio and can reach 99% of the U.S. in two days with ground shipping.

- Combine Shipments: Consolidate smaller shipments into one larger package to utilize space more effectively and lower freight charges.

- Container Utilization Techniques: Employ tactics such as pallet optimization and multi-depth box designs that maximize container space usage.

Optimizing Handling Processes to Control Costs

Handling logistics costs has a huge impact on overall operational expenses. These costs encompass the labor and materials required for the movement, storage, and processing of goods within a warehouse or distribution center.

What are Handling Costs in Logistics?

Handling costs are the expenses incurred during the loading, unloading, sorting, packaging, and inventory management of ecommerce products. Efficient handling processes can significantly reduce these costs by minimizing labor requirements and ensuring optimal use of space and resources. By focusing on optimizing handling operations, companies can achieve greater cost control and operational efficiency within their supply chain.

Businesses need to dissect handling expenses to identify opportunities for cost savings. Factors contributing to these costs include:

- Labor used in picking, packing, loading, and unloading inventory

- Materials such as boxes, tape, bubble wrap, and other packaging supplies

- Equipment like forklifts, conveyor belts, and shelving units

- Utilities, accounting for lighting, heating or cooling, and equipment operation within the handling areas

Managing Handling Expenses

Logistics is an ongoing process, and you should always make strategic adjustments to your approach to lower costs. Consider these tactics:

Streamlining Packaging Techniques

- Evaluate Packaging Needs: Assess the necessity of packaging materials to ensure they’re not excessive while still providing adequate protection.

- Standardize Packaging Sizes: Reduce inventory of packaging materials by adopting a few standard sizes that fit most products.

- Automate Packing Processes: Implement machinery that can quickly assemble boxes, insert products, and seal packages.

- Bulk Purchasing: Acquire packaging materials in larger quantities to benefit from volume discounts.

- Eco-Friendly Materials: Opt for sustainable materials that are often more cost-effective and can also appeal to environmentally conscious consumers.

Minimizing Material Use

- Choose lightweight but durable packaging options that reduce material usage without compromising product safety.

- Implement package design innovations that require less filler material by better conforming to the shape of the products.

Labor Efficiency

- Train staff in best practices for material handling to boost productivity and reduce waste.

- Apply ergonomic principles to workstations to minimize worker fatigue and injury risk, which can lead to lower healthcare costs and absenteeism.

Equipment Optimization

- Regular maintenance schedules ensure equipment operates at peak performance levels, avoiding costly downtime.

- Upgrade to energy-efficient models where possible to lower utility expenses associated with handling processes.

Reducing ecommerce operational costs requires a balanced approach that maintains service quality while cutting unnecessary expenses. Consider these methods:

- Invest in Automation: Reduce manual work through AI-driven inventory management and chatbots for customer service.

- Outsource Non-Core Activities: Use 3PL providers for warehousing and order fulfillment.

- Optimize Multi-Channel Selling: Use centralized order management systems to streamline operations across multiple sales channels.

- Reduce Packaging Waste: Switch to right-sized packaging and sustainable materials to cut shipping costs.

The Role of Technology and Automation in Ecommerce Cost Optimization

With tighter profit margins, businesses rely more on technology and automation to lower expenses. These tools help companies save money by making processes smoother, eliminating inefficiencies, and reducing mistakes made by humans.

How Technology is Changing Ecommerce

Ecommerce technology has completely transformed how businesses operate all over the world. It provides new and creative ways to save money and make operations run more smoothly. From keeping track of inventory to handling orders, technology-driven solutions are helping ecommerce businesses save a lot of money.

The Importance of Inventory Management

One area where technology is extremely helpful is in managing inventory. Having too much stock ties up money that could be used elsewhere and takes up valuable space. Plus, products can become outdated and go to waste if they’re not sold quickly enough. By using advanced software systems for inventory management, businesses can:

- Make sure stock levels are always accurate

- Automatically reorder products when they’re running low

- Avoid having too much or too little stock

- Keep track of inventory in real-time across different locations

These benefits directly lead to cost savings by reducing the need for storage space, freeing up money that was tied up in excess stock, and preventing lost sales because products were out of stock.

The Power of Automation in Ecommerce

Another way technology helps save money is through smart automation. Automation technologies like robots, tools powered by artificial intelligence (AI), and automated warehouse systems all help lower labor costs and make operations more efficient.

For example, robotic process automation (RPA) can take care of repetitive tasks like entering data or processing orders. This allows employees to spend their time on more complex tasks that bring value to the business and make customers happier.

AI-powered tools that use predictive analytics can give insights into customer behavior patterns, making it easier to predict when demand for certain products will go up or down. With this information, businesses can adjust their inventory levels ahead of time, reducing the risk of having too much or too little stock.

AI-powered tools that use predictive analytics can give insights into customer behavior patterns, making it easier to predict when demand for certain products will go up or down. With this information, businesses can adjust their inventory levels ahead of time, reducing the risk of having too much or too little stock.

Automated warehouse systems make it possible to use space more efficiently and speed up the process of picking items for orders. This means less money spent on hiring workers and faster delivery times for customers.

The True Value of Technology and Automation in Ecommerce

It’s important to understand that technology and automation aren’t about replacing humans completely. They’re meant to work alongside us, making us more productive and helping us save money. Businesses that start using them now are likely to see higher profits and be more competitive in the future.

In the next section, we’ll explore how training employees and getting them involved can have a big impact on cost optimization in ecommerce.

Building a Culture of Cost-Consciousness: Workforce Training and Involvement

Fostering a cost-conscious culture is a transformative approach that can quickly start to lower your logistics expenses. This entails empowering the workforce with a mindset that goes beyond mere budget trimming; it’s about extracting maximum value from every available resource. One crucial strategy in achieving this is through effective workforce training in cost reduction, which aligns employee efforts with the company’s financial goals.

Value of Workforce Training

Implementing training programs specifically designed to enhance financial acuity among staff leads to informed decision-making. When employees comprehend the intricacies of cost impact, they are better equipped to identify and implement cost-saving measures. It’s essential for team members to grasp how their roles directly influence the company’s bottom line.

Optimizing Workforce Count & Skills

Rethinking workforce structure can significantly ramp up productivity and curtail costs. Consider these strategies for fine-tuning your team’s capabilities:

- Cross-Training: Equip employees with skills across multiple areas of operation. This flexible approach ensures coverage without redundancy, particularly during peak seasons or when facing unexpected staff shortages.

- Role Versatility: Foster an environment where versatility is valued. Employees adept at transitioning between roles can reduce bottlenecks and enhance workflow efficiency.

- Skill Development: Invest in training programs that broaden the skill sets within your workforce. A multi-skilled employee base reduces reliance on specialist roles, which can be costly to fill.

By focusing on enhancing workforce adaptability through training and skill development, businesses can maintain a leaner staffing model without compromising on performance.

Strategies for Fostering Cost-Consciousness

Begin promoting a culture of cost-awareness throughout your organization using the following strategies:

- Incentive Programs: Reward teams or individuals who contribute to cost-saving initiatives. Recognition aligns personal achievements with organizational objectives.

- Regular Training Sessions: Implement ongoing workshops that highlight cost control as part of operational excellence.

- Transparent Communication: Share insights into how cost efficiencies benefit the entire organization, including job security and corporate growth.

- Empowerment Through Autonomy: Encourage employees to propose and pilot their own cost-saving ideas, fostering a sense of ownership over processes.

Harnessing the collective power of a well-trained, versatile workforce is pivotal in sustaining a competitive advantage without compromising service quality or customer experience.

Partner with a Reputable 3PL to Gain the Technology, Team, and Fulfillment Network for Ultimate Cost Optimization

Choosing the right 3PL provider can be a daunting task. However, partnering with a 3PL is the ultimate way to reduce fulfillment expenses and deliver a seamless order fulfillment experience. One World Direct has more than 30 years of experience as a 3PL ecommerce fulfillment company and we can help empower you with the fulfillment network, technology, and team to improve your business and lower logistics expenses.

Schedule a consultation, and one of our fulfillment specialists will help analyze your current fulfillment processes and show you how a partnership with OWD will not only help lower costs but improve your entire fulfillment operations.

In This Article:

Subscribe to our Newsletter

Tincidunt urna mauris eu quam vulputate lobortis sit. Purus feugiat arcu nunc quisque massa ut.