In This Article:

Batch picking is a crucial warehouse-picking strategy for ecommerce businesses. By grouping multiple orders into a single batch, this method significantly reduces the time spent traveling between pick locations. This streamlined approach is essential for enhancing order fulfillment speed and accuracy, directly impacting warehouse efficiency.

Key Benefits

- Reducing Travel Time: Minimize unnecessary movements within the warehouse.

- Improving Fulfillment Speed: Accelerate order processing times.

- Leveraging Staffing Resources: Optimize labor costs by efficiently utilizing your workforce.

Challenges

- Inventory Accuracy: Maintaining precise inventory counts during batching.

- Balancing Automation and Manual Operations: Finding the optimal mix for peak efficiency.

Understanding these aspects will empower you to optimize your batch-picking process, thereby boosting your fulfillment efficiency. In this article, we’ll discuss the ins and outs of batch picking so you can improve inventory management and reduce logistics costs.

What is Batch Picking?

Batch picking is a highly efficient order fulfillment strategy in which multiple orders are grouped together for a single picking session. Instead of picking items for one order at a time, which is typical in single-order picking, batch picking consolidates several orders that share common SKUs (Stock Keeping Units). This method reduces the number of trips pickers need to make through the warehouse, significantly cutting down on travel time and increasing overall efficiency.

Key Differences Between Picking Strategies

To appreciate the value of batch picking, it’s essential to understand how it differs from other picking strategies:

- Single Order Picking: Each picker retrieves items for one order at a time. This approach can be time-consuming and less efficient, especially in large warehouses.

- Zone Picking: The warehouse is divided into zones, and pickers are assigned to specific zones. Orders are fulfilled as they pass through each zone.

- Wave Picking: Similar to batch picking, it typically involves scheduling picks based on specific criteria, such as shipping schedules or order priorities.

Batch picking stands out because it minimizes redundant travel and maximizes the efficiency of the picking process, making it particularly suitable for high-volume operations.

The Concept of Order Batching

Order batching is the crux of an effective batch-picking strategy. By grouping orders with similar item requirements, batch picking optimizes the workflow:

- Identification: Identify orders that share common SKUs.

- Grouping: Group these orders together into a batch.

- Picking: Pick all items for the batch in a single run.

- Sorting: Sort picked items into individual orders post-picking.

This systematic approach ensures that pickers spend less time navigating the warehouse and more time fulfilling orders accurately.

Real-World Examples

Consider an ecommerce fulfillment center handling thousands of D2C (Direct-to-Consumer) orders daily. Using batch picking, pickers might consolidate fifty orders that all require popular items such as electronics, accessories, or apparel. Instead of making fifty separate trips to the electronics section, they make one trip and gather all necessary items in one go.

Another example can be seen in B2B (Business-to-Business) operations where bulk orders are common. Suppose several businesses place large orders for office supplies. With batch picking, all similar office supplies needed across different business clients can be picked simultaneously, streamlining the process and reducing labor costs.

Efficient batch picking speeds up the fulfillment process and enhances accuracy by reducing human errors associated with repetitive tasks, improving customer satisfaction, and reducing return rates.

By understanding and implementing batch picking, your fulfillment process becomes more streamlined and cost-effective, setting a solid foundation for handling increased order volumes efficiently.

The Advantages of Batch Picking in Warehouse Operations

Batch picking is a crucial strategy for improving warehouse productivity. It involves combining multiple orders into one picking trip, which has several benefits for the fulfillment process. Let’s take a closer look at why batch picking is so advantageous:

1. Reducing Travel Time and Minimizing Worker Fatigue

One of the main advantages of batch picking is that it helps cut down on travel time within the warehouse. By grouping together orders that require similar items, workers can pick multiple orders in a single trip. This means they don’t have to walk back and forth across the warehouse for each individual order, saving both time and energy.

This reduction in travel time directly reduces workers’ tiredness, making them more efficient and reducing the chances of mistakes.

2. Improving Order Fulfillment Speed and Accuracy

Batch picking streamlines the picking process and helps speed up order fulfillment. Workers spend less time making repetitive trips across the warehouse and more time actually finding and gathering items.

Using technology solutions like Warehouse Management Systems (WMS) or Pick-to-Light systems can further improve accuracy. These systems guide workers through optimized pick paths, ensuring that they pick the right items every time.

3. Leveraging Staffing Resources Effectively to Lower Labor Costs

Another advantage of batch picking is that it helps warehouses better use their staff, leading to lower labor costs. By optimizing pick paths and minimizing unnecessary movement, fewer workers can handle larger numbers of orders.

Using staff efficiently means achieving higher throughput without needing to hire more people. This not only saves money on labor but also allows you to get the most out of your existing employees. For warehouses that experience fluctuations in demand or seasonal spikes, this efficient allocation of resources ensures smooth operations without relying on temporary hires or excessive overtime.

Enhancing warehouse operations through batch picking not only elevates efficiency but also delivers tangible benefits such as reduced travel time, improved accuracy, and lower labor costs.

Overcoming Challenges in Implementing an Effective Batch-Picking Strategy

Batch picking can revolutionize your warehouse operations, but it comes with its own set of challenges. Addressing these issues head-on ensures you reap the full benefits of this efficient picking method.

Maintaining Inventory Accuracy During the Batching Process

Inventory accuracy is critical. Errors in inventory can lead to mispicks, delayed orders, and, ultimately, dissatisfied customers. Here are key strategies to maintain inventory accuracy:

- Regular Audits: Conduct frequent cycle counts to ensure inventory levels match system records.

- Advanced WMS: Use a robust Warehouse Management System (WMS) that offers real-time tracking and updates.

- Barcode Scanning: Implement barcode scanning to reduce human error during the picking process.

Finding the Right Balance Between Manual and Automated Operations

Deciding between manual and automated operations can be challenging. Both have their advantages and finding the optimal mix is crucial for efficiency:

- Manual Operations: Provide flexibility and are ideal for complex or irregular tasks. However, they may increase labor costs and error rates.

- Automated Systems: Enhance speed and accuracy but require significant initial investment.

Hybrid Approach

Many warehouses adopt a hybrid approach, utilizing automated systems for repetitive tasks while relying on manual labor for more intricate activities. For instance:

- Automated Guided Vehicles (AGVs): Used for transporting goods across large warehouses, reducing travel time.

- Pick-to-Light Systems: Enhance the speed and accuracy of manual picks by guiding workers through light indicators.

Addressing these challenges head-on ensures that your batch-picking strategy not only improves fulfillment efficiency but also aligns with broader operational goals.

Best Practices for Optimizing the Batch Picking Process

Designing an Efficient Warehouse Layout for Streamlined Batching

Maximizing your warehouse layout is critical for effective batch picking. Strategic placement of high-demand items near packing stations reduces travel time, enhancing productivity. Implementing a zoned layout, where the warehouse is divided into specific areas based on product types or order frequency, can further streamline operations.

Key considerations:

- ABC Analysis: Identify and categorize inventory based on picking frequency. Place ‘A’ items (high-frequency) closest to dispatch areas.

- Narrow Aisles: Optimize aisle width to allow easy navigation while maximizing storage space.

- Ergonomic Design: Ensure that shelving heights and workstation layouts minimize worker strain.

Utilizing Technology Solutions like Warehouse Management Systems and Pick-to-Light Systems

Adopting advanced technology solutions is indispensable for efficient batch picking. Warehouse Management Systems (WMS) and Pick-to-Light systems provide real-time data, improving accuracy and speed.

Benefits of a Robust WMS:

- Real-Time Inventory Tracking: Automatically updates stock levels, reducing discrepancies.

- Order Prioritization: Facilitates dynamic batching based on order urgency and shipping deadlines.

- Labor Management: Allocates tasks efficiently, ensuring optimal use of the workforce.

Advantages of Pick-to-Light Systems:

- Visual Cues: Lights guide workers to the precise location of items, minimizing search time.

- Error Reduction: Significantly lowers the risk of picking errors by providing clear instructions.

- Scalability: Easily adaptable to various warehouse sizes and complexities.

Ensuring Adequate Training and Communication Among Batch Pickers

Effective training and clear communication are pivotal to the success of batch-picking operations. Comprehensive training programs ensure that workers understand the intricacies of batch-picking methods and technologies employed.

Training Essentials:

- Hands-On Sessions: Practical training on WMS and Pick-to-Light systems helps in mastering their usage.

- Safety Protocols: Regularly update staff on safety measures to prevent workplace injuries.

- Continuous Improvement: Encourage feedback and conduct refresher courses to keep skills up-to-date.

Communication Strategies:

- Daily Briefings: Short meetings at the start of shifts to discuss daily goals and any issues encountered.

- Digital Communication Tools: Utilize apps or intranet systems for instant updates and task allocations.

- Feedback Loops: Establish channels for workers to report challenges or suggest improvements.

Need Help With Order Fulfillment?

Batch picking is crucial for achieving high levels of efficiency in today’s competitive market. It can transform your warehouse operations by:

- Reducing travel time

- Minimizing worker fatigue

- Leveraging staffing resources effectively

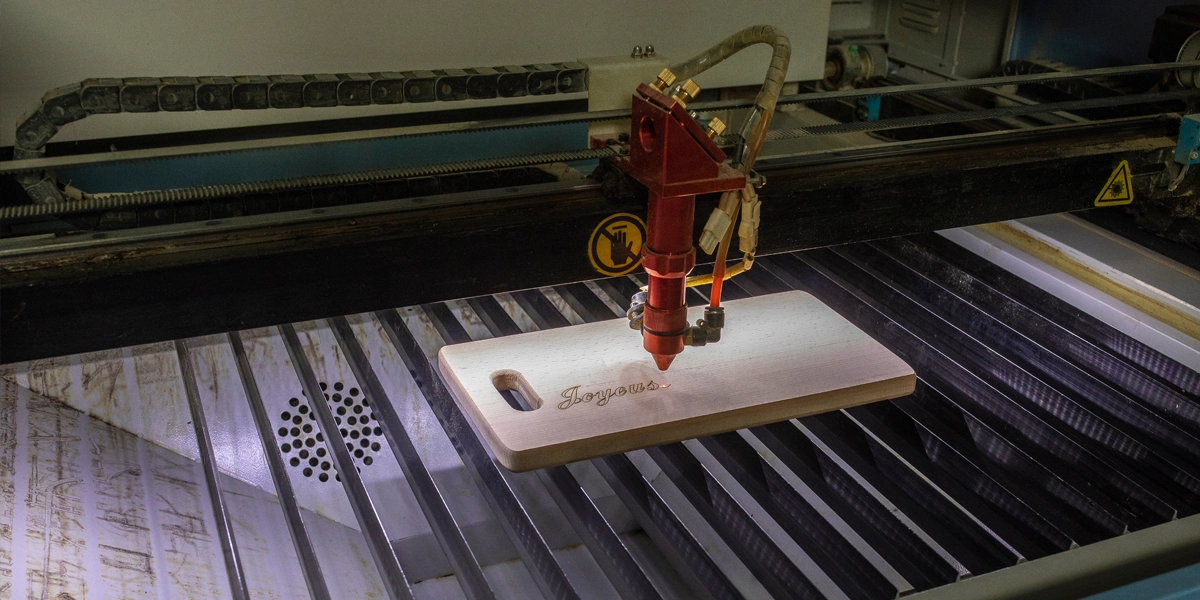

Take the next step towards optimizing your fulfillment process. Book a call with a fulfillment expert at One World Direct to explore not only batch picking but also how our personalized-to-consumer (P2C) fulfillment and call center services can elevate your business. P2C fulfillment allows you to offer easy ecommerce personalization to your shoppers so they can customize your products with personalized engravings, embroidery, direct-to-object printing, and include personalized greeting cards in each order. You can also use our US-based call center to handle all your customer queries through phone, chat, and email.

Start using batch packing and our comprehensive fulfillment services to lower logistics costs, ship faster, and improve customer satisfaction! Schedule a call, today!

In This Article:

Subscribe to our Newsletter

Tincidunt urna mauris eu quam vulputate lobortis sit. Purus feugiat arcu nunc quisque massa ut.