In This Article:

When Amazon officially launched its 4.5-million-square-foot Robotics Sortable Fulfillment Center outside Los Angeles in October 2024, there was a marching band and dance team on hand to help celebrate the largest warehouse in the U.S.

If that massive scale suggests a correlating number of employees driving around in forklifts, think again. While Amazon certainly relies on Powered Industrial Trucks (PIT) in its warehouses, more and more of them are autonomous – and as the name implies, the Robotics Sortable Fulfillment Center is “staffed” primarily by more than 7,000 robots.

And it’s not just Amazon that has upended the expectation of what’s inside all the giant warehouses dotting the countryside, which used to be defined by shelving and forklifts.

Now it’s Automated Guided Vehicles, Autonomous Mobile Robots, AI, machine learning, and predictive analytics that are creating a faster, better, and more seamless ecommerce experience for sellers and consumers – at the same time advances in technology are enabling other consumer-focused innovations like the personalization of products (P2C) as part of the fulfillment process.

Amazon and Others Set the Standard for Warehouse Technology

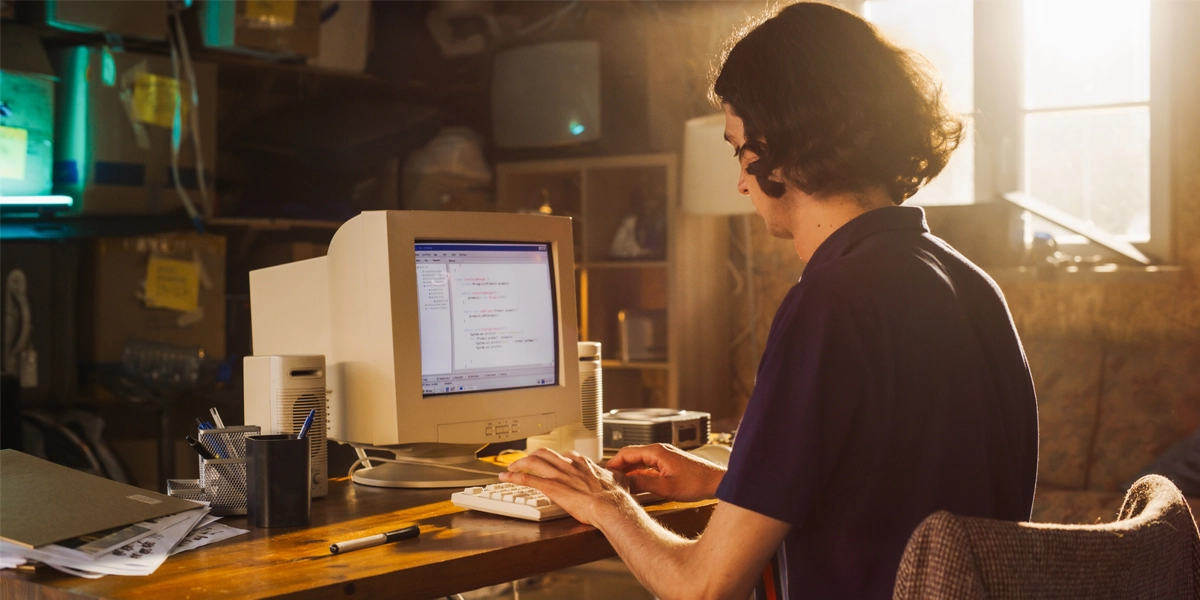

The origin story of Amazon.com being launched as an online bookseller originally called Cadabra in July 1995 in the garage of Jeff Bezos’ Washington state home is core ecommerce mythology.

Amazon’s first warehouse, the Seattle Distribution Center, was almost as analog as that garage fulfillment center with its signature “door desk” and basic office equipment. Employees picked and packed orders by walking through rows of shelves with flatbed carts, Amazon recounts online.

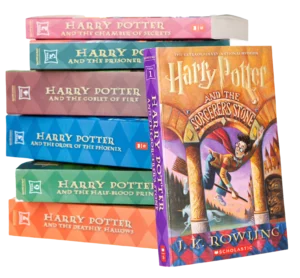

Credit the Harry Potter series of books for inspiring the first big warehouse innovation. As of 1997, Amazon’s book inventory was organized by title, which created a traffic jam when multiple pickers seeking Harry Potter and the Sorcerer’s Stone had to queue up to fulfill orders.

Credit the Harry Potter series of books for inspiring the first big warehouse innovation. As of 1997, Amazon’s book inventory was organized by title, which created a traffic jam when multiple pickers seeking Harry Potter and the Sorcerer’s Stone had to queue up to fulfill orders.

The answer was random stow, a system in which popular book titles could be clustered, or “stowed,” on any available warehouse shelf, eliminating delays and improving operations. Amazon fulfillment centers still use random stow.

What’s Next for Warehouse Technology

It’s not just Amazon that’s constantly chasing the cutting edge in fulfillment. Warehouses and fulfillment operations big and small are embracing AI, robotics, and IoT to optimize speed, efficiency, inventory tracking, and analytics.

Sure, there are still forklifts in warehouses, and while some are old school, they are mostly automated.

Last year, Walmart deployed a fleet of autonomous electric forklifts in four of its distribution centers. “AI can improve warehousing by orchestrating the automated technology,” a Walmart spokesperson told PYMNTS. ”For us, AI is helping our customers get the items they want — where, when and how they want them. The technology helps coordinate movements, optimize decisions, and, overall, make sure we can get items to our customers fast, easily and efficiently.”

Automated forklifts, meanwhile, are one innovation in a larger category of Automated Guided Vehicles (AGVs) – and join Autonomous Mobile Robots (AMRs) in handling products and materials in warehouses and distribution centers.

While both transport materials and products efficiently within warehouses, including sorting, picking, packing, and organizing inventory, one simple differentiation is that AGVs tend to follow set pathways, guided by wires or magnetic strips, while AMRs have more freedom of movement coordinated by algorithms and aided by sensors that allow them to avoid obstacles adapt to evolving environments.

AGVs and AMRs are part of a spider’s web of innovations that also include:

- Automated Storage and Retrieval Systems, which use automated equipment to move items in and out of storage.

- The Internet of Things (IoT), which uses sensors to connect devices, vehicles, appliances, and objects with software and network connectivity, enabling real-time tracking and control of warehouse operations, according to the Association for Supply Chain Management.

- Artificial Intelligence (AI) and Machine Learning (ML) to both guide the use of automated and robotic systems and engage predictive analytics to gauge demand, optimize inventory levels, and anticipate potential problems.

From the Horrea Piperataria to the Robotics Sortable Fulfillment Center

All of these 21st century innovations have propelled warehouse technology light years from the science and art of warehousing established in the ancient world by the Mesopotamians, Egyptians, and Romans.

A Roman warehouse dating to 94 AD called Horrea Piperataria, discovered hidden inside the Roman Forum and opened to the public for the first time last year was a repository for pepper and spices like cinnamon and cardamom, as well as herbs used for medicine, and incense for religious ceremonies.

There’s a through line from the Horrea Piperataria to Amazon – and there’s a case to be made that Amazon is a 20th century update of the business model pioneered by Sears Roebuck & Co. and Montgomery Ward beginning in the late 1800s. Both started in Chicago as mail-order businesses that became famous for catalogues bursting with a staggering selection of products.

There’s a through line from the Horrea Piperataria to Amazon – and there’s a case to be made that Amazon is a 20th century update of the business model pioneered by Sears Roebuck & Co. and Montgomery Ward beginning in the late 1800s. Both started in Chicago as mail-order businesses that became famous for catalogues bursting with a staggering selection of products.

A key to the success of Sears Roebuck and Montgomery Ward was something the shopping public never saw – massive warehouses that stored and shipped the things families ordered. The early Sears Roebuck operation in Chicago spanned 41 acres.

In a declaration echoed these days by Amazon, Sears claimed “the lowest prices on earth,” and from the catalog’s debut in 1888 through its demise in 1993, it sold more than 100,000 items.

One of the quirkiest starting in the late 1800s was affordable tombstones. There was even a special “Tombstones and Monuments” mailer in 1906 that promised “Direct from Quarry to Cemetery” monuments, according to Atlas Obscura.

Customers even had the option through their catalog order if personalizing tombstones with names, dates, and other inscriptions. Sears handled the engraving process in-house – foreshadowing another innovation in warehouses that’s now growing in volume and popularity.

Now Warehouses Are a Source of Personalized Products

The 3PL One World Direct is incorporating the benefits of technology into its fulfillment centers as part of a vision to help brands and e-tailers better succeed by offering personalized products – with a goal of offering P2C options (Personalized-to-Consumer) for almost every purchase.

“We’re always looking at how can we improve our process by looking at technology,” says Ryan Wheeler, Director of Personalization for One World Direct, which has warehouses/fulfillment centers in South Dakota, Ohio, and California.

That technology is focused on picking, packing, and shipping – and also increasingly on P2C, which OWD co-founder and CEO Thomas Unterseher thinks of as the key to humanizing shopping in the Digital Age.

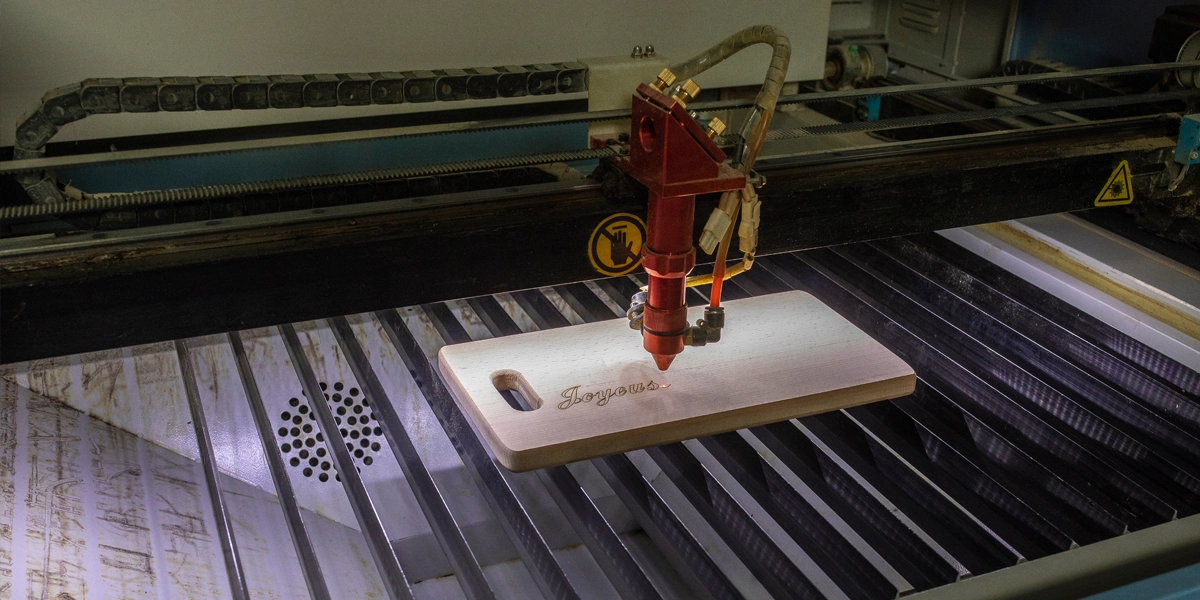

OWD offers clients software plug-ins that give consumers the ability to order Personalized-to-Consumer products as part of online shopping, and the products are personalized with processes such as direct-to-object printing, laser engraving, and embroidery in OWD warehouses as part of the fulfillment process.

It’s Wheeler’s job to determine how best to harness advances in technology and automation in the name of providing shoppers with an increasing array of personalized products – and how to expand the range of what OWD can create.

That means the beyond-forklifts components in OWD’s warehouses include the machinery that does the personalization, such as:

- Different kinds of lasers for engraving; CO2 lasers are better for organic materials like wood, leather, paper, and fabrics, while fiber lasers are better for metal and ceramics.

- Brother and Tajima Embroidery machines as part of a process that fully embodies the ethos of P2C, personalizing one product at a time.

- Direct-to-object UV ink printers, which move across surface of a product printing ink, followed by UV light that seals it so it’s hard and dry when it comes out of the printer.

The machines are connected to the server, and a suite of software gets the personalization order information from the cart to the warehouse computers and then to the P2C department, before loading jobs from the server into the printing, engraving, and embroidery machines – and then getting the finished products back out onto the fulfillment floor.

The evolution of technology within OWD’s fulfillment centers is being investigated on several fronts.

- In terms of expanding P2C options for clients, Wheeler is studying things like adding sand carving on glass (such as decanters and other items for wine lovers) and adding foil debossing to personalize notebooks with leather covers.

- Software innovations to include automating P2C job creation and creating a repository for graphics files that come in from customers.

- Development of a submissions app that will allow a potential client to inquire about specific P2C requests, such as putting consumers’ initials on the frames of glasses – as well as creating an interface where potential clients can answer questions about a product, learn the onboarding process, and see what the personalized product will look like.

- Predictive analytics and data to empower P2C clients. For example, a client with NFL licensing rights makes jackets with team logos, and as each season unfolds some logo jackets are more sought after than others. The challenge is predicting which jackets will be in demand in December and January and creating a process to manufacture those quickly to meet the demand.

About One World Direct

One World Direct has been a leader in providing fulfillment services since 1994 and allows merchants to seamlessly incorporate personalized-to-consumer (P2C) products as part of their online transaction process – turning fulfillment into a revenue enhancement while boosting customer satisfaction and loyalty. Connect with One World Direct to learn more about fulfillment services and how P2C can elevate ecommerce sales.

In This Article:

Subscribe to our Newsletter

Tincidunt urna mauris eu quam vulputate lobortis sit. Purus feugiat arcu nunc quisque massa ut.