In This Article:

Having a handy 3PL monthly checklist will help you run a more efficient and profitable operation.

2025 is already here and effective logistics will be crucial in maximizing your profits. Industry leaders understand that a well-managed supply chain not only cuts costs but also improves customer satisfaction and encourages repeat business. This checklist isn’t just a tool; it’s an investment into your bottom line.

Think of your 3PL operations like a high-performance engine. Skip the routine maintenance, and you’re gambling with your business’s future. But follow a proven monthly checklist, and you’ll spot opportunities to slash costs, delight customers, and outmaneuver competitors before they even know what hit them.

Let’s explore the monthly checks that separate thriving ecommerce operations from those barely staying afloat.

January: Strategic Planning and Inventory Assessment

Effective inventory management sets the foundation for maximizing your logistics operations. Begin the year with a comprehensive annual inventory audit to evaluate stock levels. This process identifies discrepancies, ensuring your inventory records align with physical counts. Accurate data supports decision-making and operational efficiency.

Focus on identifying slow-moving items that may weigh down storage costs and hinder cash flow. Develop targeted promotions to clear these items from your warehouse, freeing up space for high-demand products and improving financial liquidity.

Establish clear and measurable performance metrics for the upcoming year. Define key indicators such as order accuracy rates, fulfillment speed, and customer satisfaction scores. These benchmarks guide your logistics strategy, ensuring alignment with business objectives and enhancing overall service quality.

February: Cost Tracking and Budgeting

Analyzing last year’s logistics costs is crucial for setting realistic budgets for 2025. Start by reviewing fulfillment costs to identify areas for improvement. Regularly monitor shipping and storage fees, ensuring they align with your financial goals. Consider the benefits of OWD’s flexible sustainable shipping options, which can reach 99% of the U.S. within two days, potentially reducing costs.

Key Actions:

- Logistics Cost Review: Evaluate the previous year’s expenses to set new financial targets.

- Shipping and Storage Monitoring: Keep a close eye on these fees for potential savings.

- Labor Expense Evaluation: Identify opportunities to optimize labor costs without sacrificing service quality.

March: Process Optimization and Staff Training

Analyzing warehouse management processes is crucial for enhancing operational efficiency. Examine every step, from receiving to shipping, to identify bottlenecks and potential improvements. Utilize data analytics to pinpoint inefficiencies and implement automation where feasible to streamline operations.

Staff training programs are indispensable for skill enhancement. Regular workshops and hands-on training sessions ensure your team remains adept with the latest technologies and methodologies. Whether it’s finding ways to reduce picking and packing errors or implementing new fulfillment tactics such as kitting services, investing in your workforce uplifts morale and boosts productivity, directly impacting your bottom line.

Staff training programs are indispensable for skill enhancement. Regular workshops and hands-on training sessions ensure your team remains adept with the latest technologies and methodologies. Whether it’s finding ways to reduce picking and packing errors or implementing new fulfillment tactics such as kitting services, investing in your workforce uplifts morale and boosts productivity, directly impacting your bottom line.

Optimizing the warehouse layout is another key strategy. A well-designed layout facilitates better picking and packing processes, reducing time spent on each order. Consider using zone-picking or batch-picking strategies to further enhance efficiency.

Incorporating these elements into your 3PL monthly checklist ensures continuous improvement in process optimization and staff training, setting a strong foundation for sustained profitability throughout the year.

April: Technology Integration Review

A thorough technology integration review is essential for ensuring that your logistics operations run smoothly and efficiently. Start by checking that all critical systems, such as Warehouse Management Systems (WMS), EDI, and Transportation Management Systems (TMS), are fully updated and integrated. This step is crucial for maintaining smooth operations throughout the supply chain.

Assessing Software Solutions

Next, take a close look at how well your current software solutions are working. Ask yourself:

- Do these solutions meet our operational needs?

- Are there any gaps in functionality that could slow us down?

If you identify any shortcomings, it may be worth exploring new technologies like AI-driven analytics or advanced inventory management tools to improve decision-making.

Planning for Peak Seasons

As busy periods approach, it’s important to plan for technological upgrades that will strengthen system capacity and reliability. Here are some key considerations:

- Anticipate demand: Use historical data and market trends to forecast peak seasons accurately.

- Upgrade infrastructure: Identify areas where your technology infrastructure can be enhanced to accommodate increased activity and multi-channel distribution.

- Test systems: Conduct thorough testing of your upgraded systems to ensure they can handle the expected surge in operations.

By proactively addressing these factors, you’ll be better equipped to handle higher volumes during peak seasons without sacrificing performance.

Aligning Technology with Business Goals

To achieve long-term success in logistics, it’s crucial to align your technology resources with your overall business objectives. Consider the following:

- What specific goals do you want to achieve through technology?

- How can your tech infrastructure support these goals?

- Are there any areas of your logistics operations where technology can significantly improve?

By assessing these questions, you can identify potential areas for technology optimization and ensure that your investments align with your strategic goals. Additionally, regularly reviewing and updating your technology stack will help you stay ahead of industry trends, maintain a competitive edge, and deliver superior fulfillment services.

May: Customer Service Assessment and Feedback Collection

Improving customer satisfaction is crucial for optimizing your 3PL operations. A structured customer service assessment includes:

- Gathering Customer Feedback: Use various channels like surveys, direct interviews, and social media to gather insights on logistics services. This real-time feedback is essential for identifying areas that need improvement. Working with a 3PL with call center services can help you streamline customer support.

- Analyzing Service Level Performance Metrics: Examine performance metrics such as delivery times, accuracy rates, return rates, and customer service response efficiency. Understanding these metrics provides a clear understanding of where improvements are required.

- Implementing Changes Based on Customer Insights: Use the feedback to make strategic changes that align with customer expectations. Modify processes, retrain staff, or incorporate new tools to address any gaps the feedback highlights.

June: Mid-Year Performance Metrics Review

A review of performance metrics is crucial at the midpoint of the year. This is your chance to evaluate how well your operations align with the goals set in January. It’s not just about numbers; it’s about insights:

- Review Key Performance Indicators (KPIs): Dive into KPIs that matter, such as order accuracy, delivery times, and cost per shipment. Are you on track to meet the targets established during your annual strategic planning?

- Identify Strengths and Weaknesses: Use data to pinpoint areas where you excel and those needing improvement. This might reveal unexpected strengths in your 3PL processes or highlight inefficiencies.

- Adjust Strategies Based on Findings: Armed with these insights, refine your strategies for the rest of the year. Whether it’s adopting new technologies or reallocating resources, focus on enhancing efficiency and profitability.

A comprehensive mid-year performance review helps keep your logistics operations agile and responsive to market demands. This proactive approach ensures that you maximize operational efficiency and profitability as you move into the second half of 2025.

July: Summer Preparation and Peak Season Strategy Development

Peak season success starts months before the first-holiday order rolls in. Smart businesses are already analyzing last year’s data to spot opportunities and avoid bottlenecks. Map out your inventory needs, staffing requirements, and potential supply chain hiccups now, while there’s still time to course-correct and capture maximum holiday revenue.

Assessing Inventory Needs

Assessing inventory needs for major sales events such as Cyber Monday and Black Friday is imperative. Make informed decisions based on previous sales trends and current market analysis to ensure stock levels meet anticipated consumer demand.

Planning Promotional Campaigns

Planning promotional campaigns is another key component. Clear out old stock before new arrivals with targeted promotions that entice customers and optimize inventory turnover. Consider bundling complementary products, offering special discounts or limited-time offers, and creating a sense of urgency to drive sales during peak season.

Collaboration with 3PL Provider

Implement these strategies in collaboration with your 3PL provider to ensure all elements—from inventory management to customer service—are aligned for seamless execution during peak periods. This proactive approach ensures efficiency in managing peak-season logistics.

August: Cyber Monday Logistics Planning

$12.4 Billion

in sales caused delays that frustrated thousands of customers.

Cyber Monday can make or break your Q4 profits. Your fulfillment strategy needs to handle the surge – 2023’s record $12.4 billion in sales caused shipping delays that frustrated thousands of customers. Build a plan that balances fast shipping options with realistic delivery promises. Smart brands are already setting up backup carriers, planning overtime shifts, and staging critical inventory to ensure orders flow smoothly during the year’s biggest online shopping day.

Key Areas to Focus On

1. Shipping Options

Optimize delivery methods from the first mile to the last mile to guarantee timely arrivals. Consider offering expedited services or flat-rate shipping to attract more shoppers.

2. Fulfillment Strategies

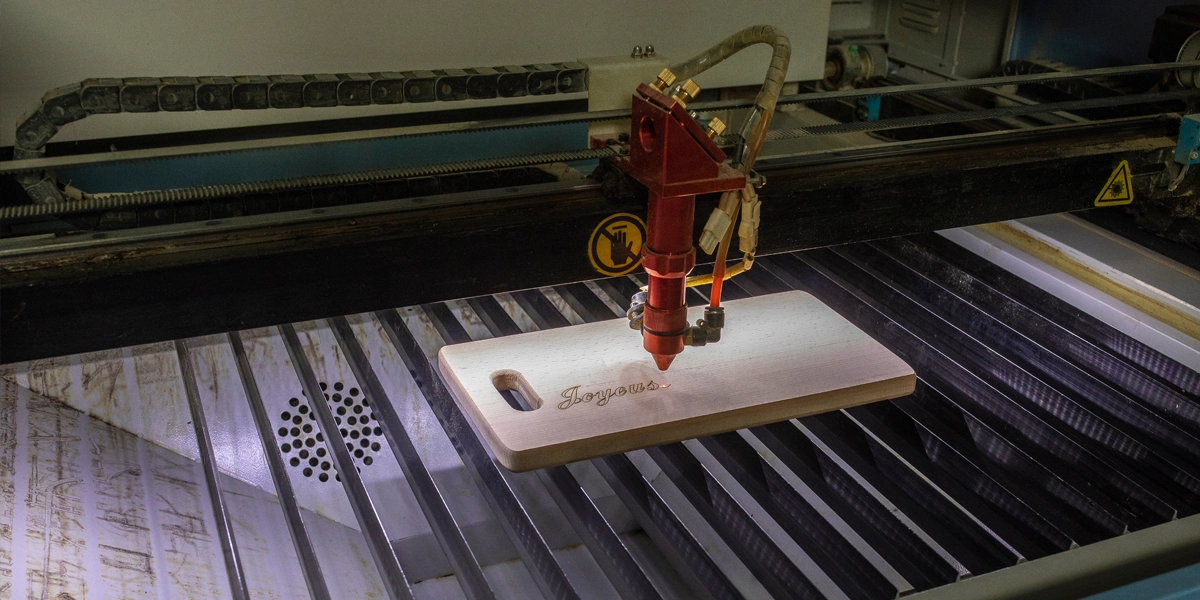

Choosing a 3PL often feels like a necessary cost of doing business, but P2C (Personalized-to-Consumer) fulfillment flips that narrative by transforming fulfillment into a profit center. With P2C, you’re not just shipping orders—you’re offering personalized experiences that customers happily pay extra for, turning a routine service into a money-maker. Best of all, the costs are passed through to your customers, so it’s pure profit for your bottom line. It’s the smarter, more profitable way to approach ecommerce fulfillment.

Integrate P2C services for seamless product personalization. Visitors can customize your products with personalized engravings, embroidery, custom packaging, and greeting cards to increase average orders and generate natural word-of-mouth marketing.

3. Staffing Levels

Align staffing plans with anticipated order surges. Ensure adequate personnel across all touchpoints—from pick and pack to customer service—to maintain operational efficiency.

4. System Testing

Conduct rigorous testing of all systems to confirm they can handle increased traffic. This includes stress-testing order management systems, ensuring API integrations function flawlessly, and verifying that customer interfaces remain responsive.

By focusing on these aspects, you’re well-positioned to capitalize on the Cyber Monday rush, turning logistical challenges into opportunities for profit maximization.

September: Holiday Season Readiness Check

As the holiday season approaches, a meticulous holiday season preparation check becomes crucial. Your 3PL monthly checklist should prioritize conducting a final review of inventory levels to ensure stock sufficiency during the anticipated surge in demand. This step mitigates risks of stockouts and ensures seamless operations.

Ensuring all technology integrations are functioning seamlessly is another vital aspect. This includes verifying that your order management systems, shopping cart plugins, and communication tools are up to date and properly synchronized. A glitch-free tech ecosystem supports efficient order processing and real-time tracking.

Ensuring all technology integrations are functioning seamlessly is another vital aspect. This includes verifying that your order management systems, shopping cart plugins, and communication tools are up to date and properly synchronized. A glitch-free tech ecosystem supports efficient order processing and real-time tracking.

Establishing a robust communication plan with customers regarding shipping deadlines is essential for managing expectations. Timely updates about order statuses and potential delays enhance customer satisfaction and loyalty, critical during peak seasons. Clear, proactive communication helps set realistic delivery timelines and reduces pressure on logistics operations during high-demand periods.

October: Black Friday Preparation

Black Friday strategy execution is crucial to maximize profitability and ensure seamless operations. Effective management of 3PL during Black Friday involves several key strategies:

Stocking Inventory with Precision

Achieving success in Black Friday promotions relies on meticulous inventory management. Ensure popular products are well-stocked to meet demand while utilizing historical data to predict trends and adjust inventory levels accordingly.

Monitoring Shipping Processes

During high-demand days, be prepared to closely monitor shipping processes. Implement real-time tracking systems to detect bottlenecks and ensure timely deliveries, maintaining customer satisfaction.

Adjusting Staffing Levels

Demand spikes necessitate flexible staffing solutions. Evaluate peak times based on past data and adjust workforce schedules to maintain efficiency without compromising service quality.

November: Post-Peak Analysis and Continuous Improvement

Retailers increasingly initiate Black Friday promotions earlier in the year, aiming to distribute the logistical burden on both their internal teams and shipping carriers. This earlier onset allows for a more timely assessment of sales performance compared to previous years. After your promotions wrap, it’s important to take some time to analyze how things went and find ways to improve. This is known as post-peak analysis. Here’s what you should do:

Analyze Performance Data

Start by looking closely at the performance data from Black Friday and Cyber Monday. This data holds valuable information that can help you understand what worked well and what didn’t.

- Sales Volume and Trends: Identify which products sold better than expected and which ones didn’t perform as well.

- Operational Efficiency Metrics: Assess key metrics such as how quickly orders were fulfilled, how accurate shipping was, and how responsive customer service was.

Identify Areas for Improvement

With the insights gained from the analysis, you can now identify specific areas that need improvement.

- Process Improvements: Find out where there were bottlenecks or delays in your operations during peak times and develop solutions to streamline those processes.

- Staffing Adjustments: Evaluate whether your staffing levels were sufficient during busy periods or if additional training is necessary for your team members.

Prepare Reports with Actionable Recommendations

Once you have completed the analysis and identified areas for improvement, it’s time to document your findings and recommendations in comprehensive reports. These reports should be shared with relevant stakeholders such as management, logistics teams, and any other parties involved in the operations.

The goal of these reports is twofold:

- To communicate key insights from the analysis

- To provide actionable recommendations that can be implemented to enhance future logistics operations

By doing this, you ensure that everyone is on the same page regarding what went well and what needs attention to achieve better results next time around.

December: Year-End Review and Future Planning

Strategic planning for the next year begins with a comprehensive year-end review. This involves summarizing key performance metrics from the past twelve months, providing a clear picture of successes and areas for improvement.

1. Performance Metrics

Identify patterns in inventory management, shipping efficiency, and customer satisfaction. Utilize these insights to refine operational strategies.

2. Goal Setting

Establish new objectives based on the data-driven insights gained during the review. These goals should be ambitious yet achievable, aligning with both long-term vision and short-term needs.

3. Logistics Strategies

Develop logistics strategies designed to enhance efficiency and profitability. Consider incorporating advanced technologies, such as automation or AI-driven analytics, to optimize operations.

This approach ensures that your 3PL monthly checklist remains robust and adaptive, setting the tone for a successful year in logistics management. By focusing on continuous improvement, you can maximize profits and elevate service levels in 2025.

Are You Ready for 2025?

Take the first step toward transforming your fulfillment strategy by booking a consultation with OWD.

Why Choose OWD?

- Comprehensive Solutions: From D2C to B2B we provide seamless, global fulfillment services.

- Profit-Driven Fulfillment: Transform order fulfillment into a revenue-generating asset with P2C fulfillment.

- Exceptional Customer Experience: Enhance service with our expert account management and contact center.

With cutting-edge technology, a vast warehouse network, and tailored strategies, OWD delivers speed, reliability, and solutions that scale with your business. Whether you’re a global D2C brand or a B2B enterprise, partner with OWD in 2025 and transform your ecommerce business.

In This Article:

Subscribe to our Newsletter

Tincidunt urna mauris eu quam vulputate lobortis sit. Purus feugiat arcu nunc quisque massa ut.