In This Article:

Outsourcing fulfillment can be a game-changer or a disaster. The difference often comes down to who you choose as your third-party logistics (3PL) partner. Many brands make the mistake of selecting a 3PL based solely on price, only to find themselves trapped in a cycle of delays, poor service, hidden fees, and lost revenue.

We sat down with Amber Fullerton, Chief Customer Officer at One World Direct (OWD), to talk about the biggest mistakes brands make when choosing a fulfillment partner. With over two decades of industry experience and a direct line to ecommerce brands of every size, Amber has seen what happens when logistics go wrong and the dire consequences that can sink ecommerce brands.

We sat down with Amber Fullerton, Chief Customer Officer at One World Direct (OWD), to talk about the biggest mistakes brands make when choosing a fulfillment partner. With over two decades of industry experience and a direct line to ecommerce brands of every size, Amber has seen what happens when logistics go wrong and the dire consequences that can sink ecommerce brands.

Whether you’re evaluating your first fulfillment partner or reconsidering your current one, this Q&A offers a behind-the-scenes look at what really matters when choosing a 3PL.

Amber:

Choosing a 3PL that lacks experience or longevity is a big mistake. Fulfillment is complex, especially if you’re dealing with vendor compliance, evolving retailer requirements, or multi-channel operations. A newer 3PL might not be equipped to handle those nuances. You want a partner who understands the business and can adapt as your needs change.

Another mistake is not digging deep into the operational cycle during the sales process. Brands should request a comprehensive demonstration of the system, from start to finish. How are products received? What happens if there’s an inventory discrepancy or a damaged shipment? How do you enter an order, and what happens if it doesn’t ship? What’s the return process, and what happens to damaged inventory? These questions should be clearly answered and well-documented.

Amber:

Unfortunately, yes—often. One client came to us after their previous 3PL let their inventory sit on the dock for over a month. The inventory was physically there, but it wasn’t received into the system, so every customer order went on backorder. They lost hundreds of thousands in sales.

Another brand had to pull back their Q4 marketing efforts because their 3PL couldn’t keep up with peak season volume. They chose to take fewer orders rather than risk customer backlash from late shipments. That tells you how serious fulfillment failures can be.

Amber:

Price shopping seems logical, but fulfillment pricing is rarely apples to apples. Each 3PL packages services differently, and the cheapest option often lacks the support, service levels, or infrastructure you need.

You get what you pay for. Lower-cost providers may not invest in technology, security, or their people. That leads to poor communication, missed SLAs, and unpredictable operations. If your inventory sits for weeks or orders don’t ship, and you don’t know why, don’t be surprised. A slightly higher monthly cost is worth it if it means reliability and peace of mind.

Amber:

Ask for a demo of the entire order cycle. Don’t just review a PDF of features, actually see the systems in action.

Ask to meet the person who will manage your account. That relationship will impact your daily operations.

Request a sample invoice. Contracts and pricing sheets rarely show the full picture. Sample invoices will reveal the hidden fees or add-ons you might otherwise miss.

Lastly, come prepared with “what if” questions. What if a shipment is lost? What if there’s a system outage? What’s the escalation path? Great 3PLs have clear, documented answers for these questions.

Amber:

Most brands don’t ask enough about communication. They ask about pricing, systems, and SLAs, but not how issues are resolved or who they’ll talk to when something goes wrong.

How are order issues handled? What’s the expected turnaround time on responses? If you have a time-sensitive question about a customer shipment, will you get an answer in an hour or three days?

That communication flow is everything. You need a fulfillment partner who acts like an extension of your team, not a black hole where issues disappear.

From missed shipments to marketing slowdowns, Amber’s insights reveal the high stakes of choosing the wrong logistics partner. The wrong 3PL can cost you far more than their invoice suggests, damaging your brand, losing sales, and eroding customer trust.

So what should brands focus on instead? Let’s dive into the top 5 mistakes ecommerce brands make when choosing a 3PL—and how to avoid them.

Mistake #1: Prioritizing Low Upfront Costs Over Long-Term Value

Chasing the cheapest 3PL might seem smart until the hidden costs catch up. Many ecommerce brands choose low-cost providers, hoping to save money out of the gate. What looks like savings on paper can trigger major headaches once orders start shipping.

Hidden Costs in Fulfillment Go Beyond the Invoice

The real price of fulfillment isn’t just the base rate for pick, pack, and ship. Additional costs can quickly add up when you include:

- Incorrect shipments leading to returns and replacements

- Delayed orders causing customer complaints or lost sales

- Extra staff hours spent fixing mistakes or answering angry emails

- Rushed shipments to make up for slow processing

- Damage to brand reputation from poor unboxing experiences

Brands that cut corners on fulfillment often face a flood of indirect expenses. These hidden costs in fulfillment quietly erode profit margins and chip away at customer trust.

Financial Penalties Can Outweigh Any Initial Savings

When a 3PL underperforms, every error increases your total cost of fulfillment. Consider these common scenarios:

- Order Errors: A fashion brand saves 10% per order by choosing a bargain 3PL. Within months, error rates increase, such as incorrect sizes shipped, missing items, and mislabeled packages. Each mistake triggers return shipments, refunds, and hours spent on customer service.

- Slow Delivery: A specialty food company picks the lowest bidder whose warehouse is far from key customers. To hit promised delivery windows, they pay for overnight shipping at peak rates, wiping out any initial savings.

- Brand Damage: An eco-friendly skincare brand switches to a low-cost provider that skips quality checks and uses generic packing materials. Loyal customers post photos online of products arriving damaged or without instruction inserts. Negative reviews impact new customer acquisition.

Each example highlights how short-term thinking leads directly to financial penalties, ranging from direct fixes to long-lasting brand damage.

Why Value Outlasts Price in Fulfillment Partnerships

Choosing a 3PL should never hinge on invoice price alone. Smart brands assess the total cost of fulfillment, factoring in all risks and downstream effects:

- Service reliability and error rates

- Speed and flexibility during high-volume periods

- Ability to personalize packaging or experiences for higher AOV (average order value)

- Customer loyalty is impacted by consistent delivery excellence

A partner invested in your success often saves you more over time by preventing costly slip-ups and protecting your brand’s reputation.

Ignoring these long-term implications allows hidden costs in fulfillment to spiral out of control, making that initially cheap option anything but affordable as your business grows.

Customer satisfaction and loyalty isn’t solely about offering low prices; it’s about providing value throughout the entire customer journey. This includes ensuring timely deliveries, accurate order fulfillment, and maintaining product quality.

While it may be tempting to opt for lower upfront costs with a cheap 3PL provider, this decision often leads to larger financial burdens down the line.

Mistake #2: Ignoring Total Cost of Fulfillment (TCF)

Total Cost of Fulfillment (TCF) is more comprehensive than just the basic fees charged by a 3PL for packing and shipping. It encompasses every single expense, both direct and indirect, incurred throughout your fulfillment process.

This includes costs such as:

- Storage fees

- Pick and pack charges

- Returns handling expenses

- Error resolution costs

- Customer service escalations

- The impact of brand damage resulting from poor execution

Why TCF Is Important for Your Brand

Brands that overlook TCF often find themselves facing various challenges, including:

- Revenue leaks: Missed shipments and damaged goods lead to refunds or replacements.

- Customer loyalty erosion: Delays, errors, and inconsistent experiences drive customers towards competitors.

- Operational chaos: More errors result in increased calls, emails, and time spent fixing issues instead of focusing on business growth.

A low upfront invoice may conceal these losses until they become evident in declining profit margins or negative reviews.

The Risks of Ignoring TCF: Errors and Brand Damage

Every mistake in fulfillment chips away at customer trust. Incorrect items shipped, orders lost during transit, or poorly packaged deliveries all contribute to:

- Lost repeat sales: A single bad delivery can turn a loyal customer into a critic.

- Expensive support interventions: Each error requires staff hours to resolve (hours that come at a cost).

- Brand reputation hits: Social media amplifies every negative experience.

By ignoring TCF, brands remain unaware of these costs until it’s too late.

How to Calculate TCF: Key Components

To make informed decisions, brands need to look beyond surface-level prices. Here’s how to evaluate true TCF:

Direct Costs

- Storage fees

- Pick/pack charges

- Packing and kitting materials

- Shipping rates

- Return processing expenses

Indirect Costs

- Error rates (wrong item, delayed delivery)

- Customer service workload related to fulfillment issues

- Lost revenue from canceled orders or churned customers

- Costs associated with a damaged brand reputation

Opportunity Costs

- Time wasted on firefighting instead of scaling your business

- Missed upsell/cross-sell opportunities due to poor unboxing or personalization

Quick Tips for Evaluating TCF

- Track every order touchpoint where errors could happen.

- Ask potential 3PLs about their error rate statistics and client references.

- Request information on the average time-to-resolution for common problems.

- Calculate the average cost per incident and project it across your annual order volume.

Mistake #3: Overlooking the Impact of Location on Customer Satisfaction

Warehouse Location Matters

Choosing a 3PL with strategically located warehouses is crucial. The geographical position of these facilities influences shipping costs and delivery times, directly affecting customer satisfaction.

Consequences of Poorly Located Logistics Partners

- Inflated Expenses: Brands may face higher freight charges if their 3PL’s warehouses are distant from their customers.

- Expedited Shipping Costs: To meet delivery expectations, brands may need to incur additional costs for expedited shipping, thereby increasing their operational expenses.

Strategic Selection Tips

- Evaluate Proximity to Major Markets: Ensure your 3PL’s warehouses are near your target markets. This reduces shipping time and costs.

- Analyze Shipping Routes: Understand common shipping routes used by the 3PL. Efficient routes mean faster deliveries.

- Consider Zone-Based Pricing: Some 3PLs offer pricing based on zones. Choose a provider with favorable zone pricing for your key markets.

Selecting a 3PL with well-positioned facilities optimizes cost efficiency and enhances service excellence, ensuring happier customers and smoother operations. OWD has three fulfillment center locations (in California, South Dakota, and Ohio) and can reach 99% of the U.S. within two days with ground shipping.

Mistake #4: Not Evaluating Technology Integration Capabilities Enough

Brands expect flawless order fulfillment. Customers demand fast, error-free shipping. Behind the scenes, this level of precision relies on the right technology stack; yet, many brands underestimate the critical importance of these systems when selecting a 3PL.

Why Warehouse Management Systems (WMS) and Transportation Management Systems (TMS) Matter

- Accuracy and Speed: A robust WMS tracks inventory in real time, reduces picking mistakes, and keeps shrinkage low. This means fewer lost packages and happier customers.

- Cost Control: TMS platforms optimize shipping routes, cut down on unnecessary freight charges, and help brands avoid last-minute expedited fees.

- Scalability: As your business grows, advanced systems adapt to higher volumes without breaking down under pressure.

A 3PL with outdated or fragmented tech is a risk. You’ll see it in missed shipments, slow updates, and frequent manual errors. The damage? Bad reviews, costly returns, lost repeat business.

ERP System Integration: The Heartbeat of Modern Fulfillment

Your brand likely operates with an Enterprise Resource Planning (ERP) system—think NetSuite, SAP, or Microsoft Dynamics. If your 3PL’s technology can’t “talk” to your ERP:

- Inventory data gets out of sync

- Orders slip through the cracks

- Customer service teams scramble to explain delays

Seamless integration allows for:

- Instant order transmission from your store to the fulfillment center

- Real-time inventory updates across all sales channels

- Automated tracking updates sent straight to your customers

- Data-driven forecasting that keeps you stocked and responsive

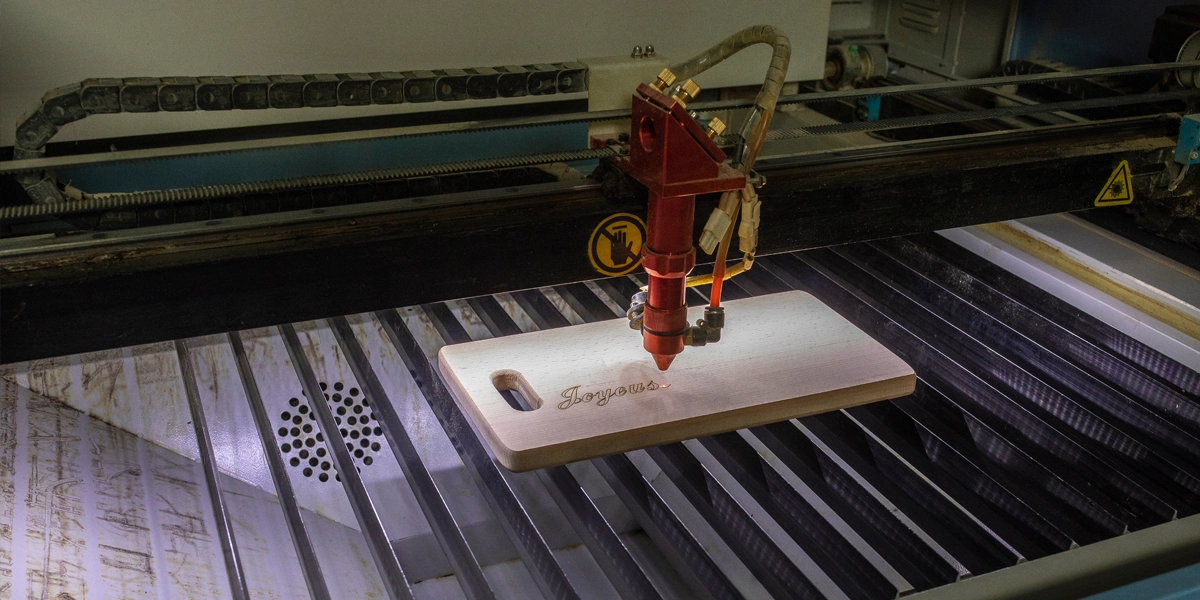

OWD is the only 3PL that offers personalized-to-consumer (P2C) fulfillment, which integrates with ecommerce platforms. P2C allows for seamless product personalization. Shoppers can customize their products with engravings, embroidery, or direct-to-object printing to create luxury, artisanal, one-of-a-kind products. It’s an easy way to boost average order values, generate naturally word-of-mouth marketing, and set your brand apart.

Questions to Ask Before Committing

Brands should never assume all third-party logistics partners offer equal tech capabilities. Protect your reputation by asking:

- Which warehouse management system do you use? Is it cloud-based?

- How do you handle integrations with my ERP system?

- Can you support custom workflows or value-added services (like P2C features)?

- What is your protocol for technology downtime or errors?

Red Flags That Signal Trouble

- Manual file transfers instead of automated syncing

- No direct API access for ecommerce platforms

- Vague answers about integration timelines or support resources

- No technical support team to guide you through setup and ongoing questions

Choosing a logistics partner with weak technology leaves your brand vulnerable to profit erosion and brand damage, issues that often emerge only after customer trust has been lost.

Smart brands vet their 3PLs’ technology as rigorously as they audit costs or locations. The difference shows up in customer loyalty, AOV gains, and smoother peak seasons, every single year.

Mistake #5: Lack of Clear Communication Protocols Established with Your Chosen Provider

Clear communication with your 3PL provider is crucial for maintaining smooth operations. When issues arise during order fulfillment or transportation stages, prompt resolution depends heavily on well-defined communication channels.

OWD prioritizes client communication for both our clients and their customers. Our call center services offer personalized support to your customers via email, live chat, and phone calls. Additionally, our fulfillment clients have a dedicated American account manager as a direct point of contact for any questions or to coordinate fulfillment efforts.

Why Communication Matters

- Timely Issue Resolution: Without clear protocols, small problems can escalate quickly. Addressing these issues promptly prevents disruptions and keeps your customers satisfied.

- Operational Efficiency: Communication gaps can lead to inefficiencies, which impact delivery times and customer service.

Role of a Dedicated Account Manager

A dedicated account manager acts as a single point of contact between your brand and the 3PL provider. This role is essential for:

- Smoother Interactions: Direct communication with an assigned manager ensures that any questions or concerns are handled efficiently.

- Faster Problem Solving: An account manager familiar with your specific needs can expedite solutions, minimizing downtime.

- Enhanced Collaboration: Stronger relationships fostered through dedicated contacts lead to better collaboration and understanding between parties.

How to Choose a 3PL Provider with Strong Communication Protocols

When evaluating potential 3PL providers, consider the following:

Ask About Their Communication Channels

- Do they offer direct lines to support staff?

- Are they available via phone, email, and chat?

Inquire About Dedicated Account Management

- Will you have a single point of contact?

- How often will you meet or communicate with this manager?

Evaluate Their Responsiveness

- How quickly do they respond to queries?

- Request references from other clients to gauge their experience.

Assess Their Problem-Solving Capabilities

- What processes do they have in place for handling issues?

- Ask for examples of how they've resolved past challenges.

Choosing a 3PL provider like One World Direct, known for its excellent communication protocols and dedicated account management, ensures that your brand remains agile and responsive to customer needs. This strategic choice enhances loyalty, increases average order value (AOV), and boosts repeat sales—all without the pitfalls of poor communication.

Effective communication isn’t just about solving problems; it’s about building a partnership that drives success. Prioritize providers who understand this dynamic and offer robust support systems tailored to your needs.

Schedule a Consultation and Find Out if We are the Right 3PL for You

Choosing the right logistics partner is crucial for sustainable growth. Avoiding the top mistakes brands make when selecting a 3PL can save time, money, and protect brand reputation.

Prioritize long-term value over short-term cost savings. Conduct thorough research:

- Track records: Review client testimonials and case studies.

- Industry expertise: Evaluate their experience in your specific market.

- Technological capabilities: Ensure seamless integration with your systems.

Schedule a call with our team and discover the benefits of working with a capable 3PL like One World Direct.

In This Article:

Subscribe to our Newsletter

Tincidunt urna mauris eu quam vulputate lobortis sit. Purus feugiat arcu nunc quisque massa ut.