In This Article:

Knowing how to calculate your Fulfillment CPU (Cost per Unit) is crucial for any ecommerce business trying to increase profitability and efficiency. It plays a vital role in financial strategy, affecting pricing decisions, profit margins, and competitive positioning in the market.

In this article, we will explore the details of cost per unit, including:

- Defining Cost Per Unit: Understanding its components and significance.

- Calculation Methodology: A step-by-step guide to accurate calculation.

- Distinguishing from Price Per Unit: Understanding how each impacts your bottom line and why differentiation is important.

- Strategies for Reduction: Actionable strategies to lower your CPU.

- 3PL Partnerships: How a Third-Party Logistics provider can help reduce fulfillment costs.

This comprehensive exploration aims to equip you with the knowledge needed to optimize your operations, boost profitability, and drive growth.

What is Cost Per Unit?

Definition of Cost Per Unit (CPU)

Cost Per Unit (CPU) is a metric used to determine the average cost incurred to produce, store, and deliver one unit of a product. It encompasses both fixed costs and variable costs associated with production. Fixed costs include expenses such as rent, salaries, and overheads that remain constant regardless of the output level. Variable costs fluctuate with production volume and may encompass materials, labor, and distribution charges.

Components of CPU:

- Fixed Costs: These are stable costs that do not change with the level of production, such as lease payments for facilities or salaries for permanent staff.

- Variable Costs: Costs that vary directly with production levels—examples include raw materials, packaging, and shipping expenses.

Importance of Understanding CPU

Grasping the concept of CPU is pivotal for businesses aiming to optimize their financial performance. By analyzing and calculating CPU:

- You can make informed pricing decisions that ensure competitiveness while maintaining cost optimization.

- It aids in identifying inefficiencies within production processes by highlighting areas where cost savings can be achieved.

- Provides insights into overall business health by enabling accurate forecasts of profitability under different production scenarios.

Understanding your average cost per unit empowers you to streamline operations and develop effective pricing strategies that keep your business profitable while determining what factors are hurting your bottom line.

Cost Per Unit vs. Price Per Unit

Understanding the difference between cost per unit (CPU) and price per unit is crucial for effective pricing strategies. The unit cost includes all expenses incurred to produce a single item, including both fixed and variable costs. On the other hand, the price per unit is what you charge your customers for that item.

Unit Cost vs. Unit Price

Unit cost is the total cost to produce one unit, while unit price is the selling price per unit.

Metric | Definition | Example |

|---|---|---|

Unit Cost | Total cost per unit (fixed + variable costs). | $25 |

Unit Price | Selling price per unit. | $40 |

Profit Margin | Difference between unit price and unit cost. | $15 |

To ensure profitability, businesses must price products above the unit cost while remaining competitive.

Key Differences:

Cost Per Unit:

- Includes total fixed and variable costs.

- Directly affects profit margins.

Price Per Unit:

- The selling price set for consumers.

- Determines revenue potential.

Balancing these two metrics is vital. A well-calculated selling price per unit ensures that you cover your CPU while achieving the desired profit margins. Effective pricing strategies depend on this balance, as underestimating the CPU can lead to reduced profits or losses.

Practical Applications:

- Full Cost Pricing Example: Incorporates all production costs into the selling price to ensure profitability.

- Average Cost Pricing Purpose: Simplifies pricing by using average costs over time, aiding in stabilizing prices regardless of production fluctuations.

Use tools like a price per unit calculator or a selling price per unit calculator to make your calculations easier. Identifying each component efficiently, such as how to find variable expense per unit, allows for more accurate pricing strategies and better competitive positioning in the market.

What Is the Purpose of Average Cost Pricing?

Average cost pricing helps businesses stabilize prices by using the average cost of production over time. It ensures costs are covered without drastic price fluctuations.

Example:

A business incurs varying costs:

- January: $10 per unit

- February: $15 per unit

- March: $12 per unit

The average cost pricing approach would set the price at:

10+15+12/3=12.33

This helps maintain consistent pricing for customers while covering costs.

Full-Cost Pricing

Full cost pricing ensures that all production costs are accounted for when setting a selling price. It includes fixed costs, variable costs, and a markup for profit.

Example:

- Fixed Costs: $10,000

- Variable Costs: $20,000

- Units Produced: 1,000

- Desired Profit: 20%

Price Per Unit Calculation:

10,000+20,000/1,000 = 30

Adding a 20% profit margin:

30 × 1.2 = 36

Thus, the full cost price per unit is $36.

How to Calculate Cost Per Unit?

The CPU formula serves as a straightforward method to break down expenses and assess the financial health of your fulfillment processes.

Cost Per Unit Formula

The CPU formula is:

Cost per unit = variable cost + fixed costs / total units produced.

Example: A company has $10,000 fixed costs, $10,000 of variable costs, and is producing 500 products. $10,000+$10,000 = $20,000 total costs and $20,000/500 = $40 per unit.

How to Calculate Freight Cost Per Unit

To calculate freight cost per unit, divide your total shipping costs by the number of units shipped.

Formula:

Freight Cost Per Unit = Total Units Shipped/Total Shipping Costs

Example:

If a company spends $5,000 on freight and ships 1,000 units, the freight cost per unit is:

5,000/1,000 = 5

This means each unit incurs $5 in freight costs.

Total Fixed Costs

Definition:

Fixed costs are expenses that remain constant regardless of the volume or scale of production. These are foundational costs you incur irrespective of how many units you produce or sell.

Examples:

- Rent: The monthly lease for your warehouse or office space.

- Salaries: Wages paid to permanent staff members such as managers or administrative personnel.

- Overhead Expenses: Utilities, insurance, and other general business costs.

Accurate forecasting of fixed costs involves analyzing historical data and considering potential changes in your operational environment. Regularly reviewing contracts and agreements can also ensure these costs remain predictable.

Total Variable Costs

Definition:

Variable costs fluctuate with production output and sales volume. These expenses increase with each additional unit produced or sold, offering opportunities for optimization.

Examples:

- Production Materials: Raw materials required to manufacture products.

- Packaging: Costs associated with packaging materials specific to each product.

- Shipping Expenses: Expenses incurred for delivering products to customers, varying based on destination and shipping method.

Variable costs directly impact the overall CPU calculation. Reducing these using tactics like bulk purchasing can lead to significant savings and enhance profitability.

How to Find Variable Expense

Variable expense per unit is found by dividing total variable costs by the number of units produced.

Formula:

Variable Cost Per Unit = Total Variable Costs/Total Units Produced

Example:

If variable costs total $15,000 and 500 units are produced:

15,000/500=30

Each unit has a variable expense of $30.

How to Find Cost of Direct Materials

Direct material cost is found by summing the cost of raw materials used in production.

Formula:

Direct Material Cost = Total Raw Material Cost÷Total Units Produced

Example:

$50,000 spent on raw materials

5,000 units produced:

50,000÷ 5,000=10

Each unit incurs $10 in direct material costs.

Is Shipping a Variable Cost?

Yes, shipping is a variable cost because it fluctuates based on order volume. More orders increase shipping costs, while fewer orders reduce them.

Example:

- Shipping 500 units costs $2,500 → $5 per unit

- Shipping 1,000 units costs $5,000 → $5 per unit

Since costs scale with volume, shipping is classified as a variable cost.

How to Figure Variable Cost Per Unit

The variable cost per unit is calculated by dividing total variable costs by the total number of units produced.

Formula:

Variable Cost Per Unit = Total Variable Costs ÷ Total Units Produced

Example:

If a business has variable costs of $8,000 and produces 400 units:

8,000÷ 400=20

Each unit has a variable cost of $20.

The Importance of Cost Per Unit in Ecommerce Businesses

Understanding the importance of cost per unit for ecommerce businesses is indispensable for several reasons:

1. Pricing Strategies

Calculating CPU allows you to establish a baseline for pricing your products. Knowing your CPU ensures that your pricing covers all costs and contributes to healthy profit margins. This precision prevents underpricing, which can erode profits, and overpricing, which may deter potential customers.

2. Profitability Analysis

Accurate CPU calculations enable a clear understanding of profitability on a per-unit basis. With this insight, you can identify which products are driving profit and which are liabilities, allowing for strategic adjustments to product offerings and marketing focus.

3. Inventory Management Decisions

Effective inventory management hinges on precise CPU knowledge. It aids in determining optimal stock levels by aligning inventory investment with actual sales performance. Mismanagement here can lead to excess stock or shortages.

4. Competitive Positioning

The ability to offer competitive pricing without sacrificing margins is crucial. Understanding your CPU aids in setting prices that attract customers while maintaining a competitive edge against rivals.

By integrating these elements into your operational strategy, calculating and comprehending cost per unit becomes an accounting exercise and a strategic tool. This empowers you to make informed decisions that drive efficiency and profitability across your ecommerce business platform. Implementing an effective warehouse management system and lot management practices can help you find areas to cut fulfillment costs.

Strategies to Reduce Your Cost Per Unit

When you start to reduce cost per unit (CPU), your business will begin to thrive. Several essential tactics exist to achieve cost savings without compromising quality or customer satisfaction.

1. Optimize Sourcing Methods

Evaluate and refine your supply chain to identify cost-saving opportunities. Engage in strategic negotiations with suppliers for better pricing, bulk discounts, or longer payment terms. Consider diversifying your supplier base to foster competitive pricing and reduce dependency on single sources.

2. Negotiate Better Deals with Suppliers

Building strong relationships with suppliers opens the door for negotiating favorable terms. Utilize market research and volume commitments as leverage for price reductions or enhanced service levels. Establishing a long-term partnership can also lead to collaborative innovations that lower production costs.

3. Streamline Production Processes

Analyze current manufacturing workflows to identify inefficiencies. Implement lean manufacturing techniques to eliminate waste, reduce cycle times, and optimize resource use. Automating repetitive tasks through technology investments can reduce labor costs and increase throughput. Improving order picking accuracy, reducing picking and packing errors, or implementing sustainable fulfillment practices can contribute to significantly reducing CPU.

4. Enhance Inventory Management

Efficient inventory control minimizes holding costs and reduces the risk of obsolescence. Implement just-in-time inventory systems to align stock levels closely with demand forecasts, thus freeing up working capital and reducing storage expenses. Partnering with the right 3PL and outsourcing fulfillment can help you further lower overall costs.

How a 3PL Can Help Lower Your Fulfillment Costs

Engaging a 3PL is a strategic move that can significantly reduce your fulfillment costs. You can decrease shipping expenses and improve overall cost efficiency by leveraging their established networks and expertise. Here’s how:

Established Networks

3PLs have robust logistics networks that allow for economies of scale. They negotiate better rates with carriers due to the high volume of shipments they handle, passing these savings onto you.

Expertise in Logistics

Their specialized knowledge in supply chain management ensures that fulfillment processes are optimized, reducing waste and inefficiencies.

Beyond cost reductions, partnering with a 3PL offers several additional advantages:

- Operational Efficiency: With a 3PL managing logistics, you can focus resources on core business activities while ensuring orders are processed accurately and swiftly.

- Scalability: As your business grows, 3PLs offer the flexibility to scale operations up or down without the need for significant capital investment in infrastructure, especially during peak seasons.

- Technology Integration: 3PLs often have advanced systems and technology in place, allowing for seamless integration with your existing platforms. This streamlines order processing, inventory management, and tracking, leading to improved visibility and customer satisfaction.

- Expertise and Resources: 3PLs bring their expertise in logistics and fulfillment, ensuring efficient processes and reducing errors. They also have access to a vast network of carriers, enabling them to negotiate better shipping rates on your behalf.

- Risk Mitigation: By entrusting your fulfillment operations to a reliable 3PL, you can mitigate the risks associated with disruptions, such as natural disasters or labor shortages. They can quickly adapt to changing circumstances and minimize the impact on your business.

Lower CPU and Open Up New Profit Centers with OWD

If you are struggling to find ways to lower CPU, book a logistics consultation with our team. We can help audit your current operations and discover ways to reduce costs while implementing new profit centers for your business.

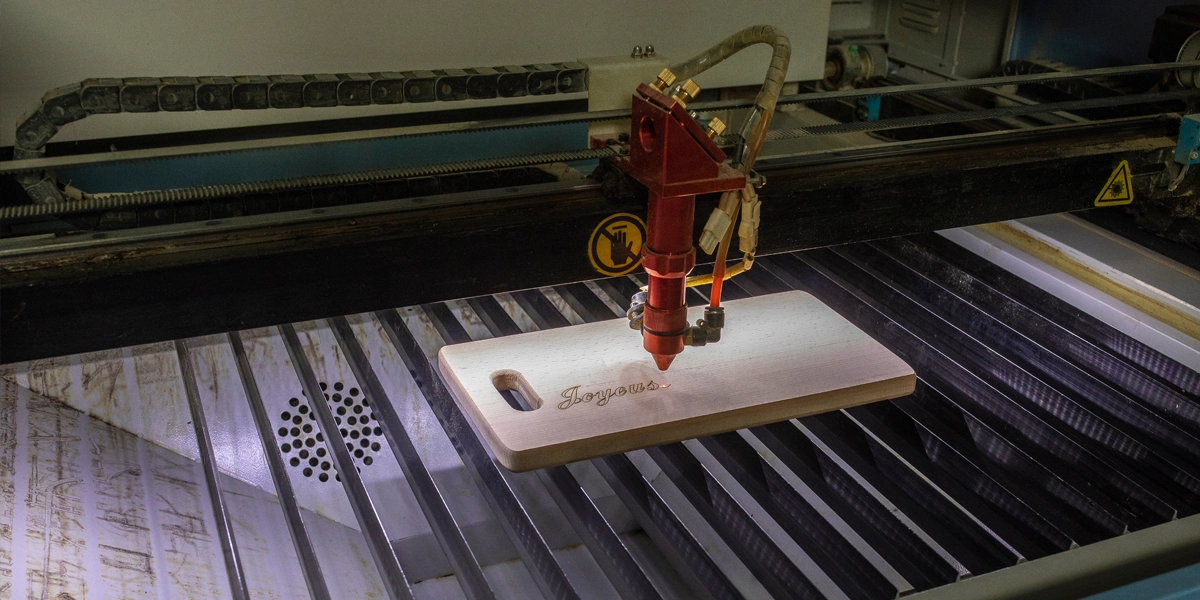

Our Personalized-to-Consumer (P2C) fulfillment services allow for easy ecommerce product personalization. Shoppers can personalize goods with custom engravings, embroidery, and direct-to-object printing and can customize packaging or include greeting cards in each order.

Ecommerce personalization is in hot demand, but few businesses can offer product personalization at an affordable cost. P2C fulfillment allows you to increase average order values and conversions and can help your brand stand out.

Schedule a time to chat, and we can discuss other ways you can start increasing profits while delivering top-rate fulfillment comparable to retail giants like Amazon or Walmart.

In This Article:

Subscribe to our Newsletter

Tincidunt urna mauris eu quam vulputate lobortis sit. Purus feugiat arcu nunc quisque massa ut.