In This Article:

Working with a 3PL with strategic fulfillment center locations can elevate your ecommerce business to the next level. 3PLs take care of everything from storing products to delivering them, freeing up businesses to focus on growing and being creative. The location of these centers is extremely important; it determines your logistics plan, shortens delivery times, and improves customer satisfaction.

Selecting a 3PL with a network of 3PL fulfillment centers can make a huge difference. This choice affects transportation costs and your delivery speed, helping you compete with big retailers like Amazon and Walmart.

It’s vital for keeping up with increasing customer demands in a fast-moving online market. Shoppers cite free shipping and speed of delivery as the two most important factors when purchasing products online. 67.77% of US shoppers value two-day shipping when shopping online, so if you can’t facilitate fast shipping, your target customers will start shopping elsewhere. [Source: Zipdo]

67.7%

of US shoppers value two-day shipping when shopping online

Discover the best 3PL fulfillment center locations and how to select the right 3PL to improve your shipping speeds. We’ll explore things like how close you are to major markets, the quality of infrastructure, and regional rules. By understanding these factors, you’ll be able to make the right move and switch to a capable 3PL that will help you meet the high standards of modern online shoppers.

Understanding 3PL Fulfillment Centers

3PL providers play a crucial role in the ecommerce ecosystem. These companies manage various parts of the supply chain, such as warehousing, inventory management, and shipping. Working with a 3PL helps businesses make their operations more efficient, lower costs, and concentrate on what they do best.

Types of Fulfillment Services Offered by 3PL Providers:

- Direct-to-Consumer (D2C): Facilitates seamless delivery from the business directly to the end customer. This model is ideal for brands looking to build strong customer relationships and maintain control over the customer experience.

- Business-to-Business (B2B): Involves handling bulk shipments to other businesses or retailers. Efficient B2B fulfillment is crucial for maintaining supply chain fluidity and meeting partner expectations.

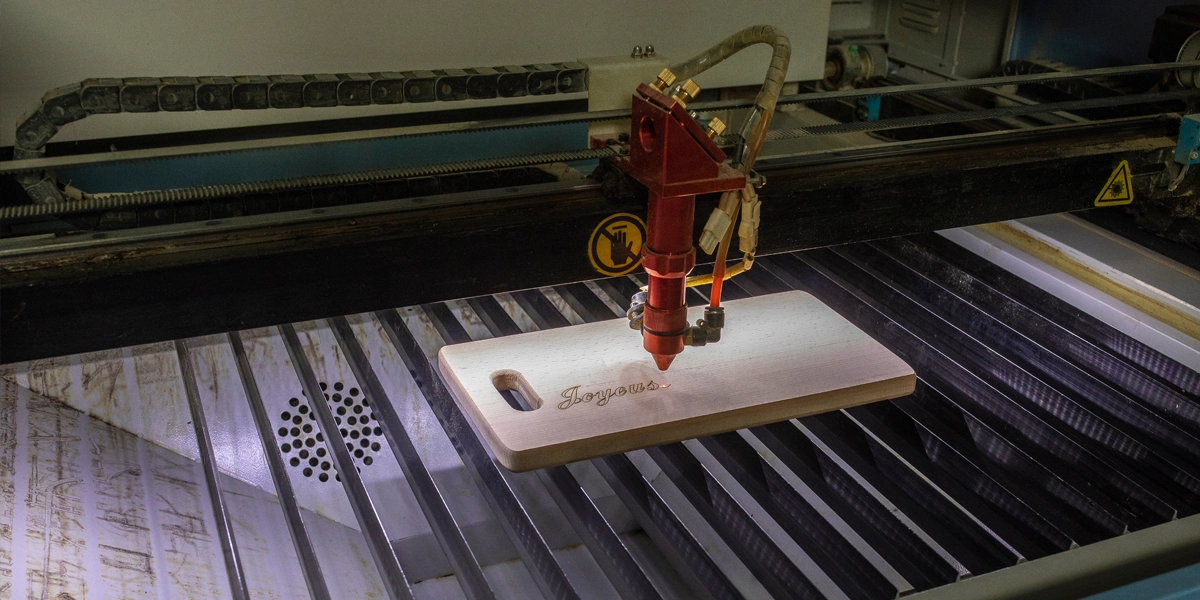

- Personalized-to-Consumer (P2C): An exclusive One World Direct service, P2C fulfillment focuses on ecommerce personalization and product customization through options such as engraving, embroidery, or direct-to-object printing. Businesses can use P2C to turn fulfillment into a new profit center. Consumers are willing to pay around a 25% premium for personalized or customized items, and 77% of consumers have chosen, recommended, or paid more for a brand that provides product personalization. [Source: Ecommerce Personalization Statistics] Elevate your product line and convert more shoppers while increasing average order values and word-of-mouth marketing with P2C fulfillment.

Why One World Direct Should Be Your Top Pick:

One World Direct stands out in the industry due to its comprehensive range of services:

- Global Fulfillment Expertise: From custom pack-outs to international shipping solutions, OWD supports both D2C and B2B operations.

- Strategic Location Reach: OWD has three fulfillment centers located in California, Ohio, and South Dakota and can reach 99% of the U.S. in two days.

- Flat-Rate Shipping: Gain predictable shipping rates and start offering overnight shipping, same-day fulfillment, and multiple shipping methods to your customers for maximum flexibility.

- The Ultimate Gift-Giving Experience: P2C lets customers customize products, and shoppers can also include custom packaging and personalized greeting cards for stunning unboxing experiences.

- Omnichannel Ecommerce Customer Service: OWD’s call center services help you deliver great customer service by handling their calls, emails and chats. It’s fully integrated with our fulfillment center for a seamless experience and we only use American agents who speak in your brand voice.

Key Factors to Consider When Choosing a Location for Your 3PL Fulfillment Center

Selecting the optimal location for your 3PL fulfillment center is a strategic decision that can influence your logistics efficiency and business success. The following key factors should be meticulously evaluated to ensure alignment with your operational goals and customer needs:

1. Proximity to Major Markets

Fast shipping times are paramount in meeting modern consumer expectations. Positioning your fulfillment center closer to major transportation hubs can enhance delivery speed, thus improving customer satisfaction. The strategic placement allows you to leverage expedited shipping routes, ensuring that products reach customers quickly.

Being near transportation hubs—such as airports, seaports, and major highways—can drastically reduce transit times and enable more sustainable fulfillment. This proximity enables seamless integration into existing logistics networks, facilitating efficient inbound and outbound freight movement.

3. Operating Costs and Profitability Factors

Operating costs vary significantly by region, including real estate prices, taxes, and utilities. A thorough cost analysis is essential to determine the most financially viable location. Lower operating costs contribute to improved profit margins, allowing for reinvestment into other areas of your business.

4. Shipping Costs and Zone Optimization

Selecting a location that minimizes shipping zones can significantly reduce carrier fees. Centralized locations often provide the best balance between cost-effectiveness and delivery speed.

5. Zoning Laws and Labor Regulations

Compliance with local zoning laws ensures that your operations align with regional regulations. Understanding labor regulations is equally important to manage workforce availability and costs effectively. These legal considerations play a crucial role in maintaining uninterrupted operations.

6. Labor Market Availability

Ensure the region has a sufficient workforce with the necessary skills for warehouse and logistics operations. Competitive labor costs and workforce stability are critical considerations.

7. Inventory Management and Demand Fluctuations

A strategically placed fulfillment center enables efficient stock distribution based on sales trends, minimizing excess inventory and ensuring availability during peak season demand.

8. Legal and Regulatory Compliance

Check zoning laws, labor regulations, and any restrictions that might impact your operations. Understanding these factors can prevent legal and logistical hurdles.

9. Competitor and Market Analysis

Research competitor fulfillment center locations to identify strategic advantages or potential oversaturation. This insight can help position your business for a competitive edge.

10. Data-Driven Location Selection

Use Geographic Information Systems (GIS) and data analytics to assess consumer density, order patterns, and logistics efficiency. These tools can provide valuable insights into optimal placement.

11. Scalability and Business Growth

Choose a location that allows for future expansion without excessive relocation costs. Scalability ensures your fulfillment operations can grow alongside your business needs.

12. Pilot Testing Before Commitment

If possible, test operations in a potential location with small-scale fulfillment to evaluate logistical efficiency, workforce performance, and overall feasibility.

Strategically evaluating these factors provides a comprehensive framework for selecting the ideal location for your 3PL fulfillment center. Each element plays a pivotal role in optimizing logistics processes, enhancing customer satisfaction, and driving business success through efficient fulfillment operations.

When Should You Consider Using Multiple Fulfillment Centers?

Implementing a multi-location strategy can unlock substantial advantages for your business, especially when dealing with a diverse and geographically dispersed customer base. Having multiple fulfillment centers is particularly advantageous in the following scenarios:

1. Expansive Customer Base

If your ecommerce platform caters to customers across various regions, multiple fulfillment centers can significantly reduce shipping times and costs. This ensures faster delivery, enhancing customer satisfaction and loyalty.

2. Scalability

As your business grows, managing inventory across several locations allows for scalable operations. It provides the flexibility to handle increased order volumes without compromising on service quality or delivery speed.

3. Risk Management

A distributed distribution network minimizes risks associated with disruptions. Natural disasters or other localized issues at one center won’t halt your entire operation.

4. Cost Efficiency

Distributing inventory closer to key markets cuts down on transportation costs, thus optimizing your logistics expenses.

Transitioning to a multi-location setup aligns with strategic growth objectives, ensuring seamless operations and competitive advantage in dynamic market landscapes.

Advantages of Partnering with a 3PL That Has Multiple Fulfillment Locations Like One World Direct

Partnering with a 3PL provider that has multiple strategically located fulfillment centers, such as One World Direct, offers unmatched benefits in terms of operational efficiency and customer satisfaction. Here’s why:

Proximity to Customers

With centers in key locations like California, South Dakota, and Ohio, your products reach customers faster. This proximity reduces shipping times and costs, ensuring your customers receive their orders promptly.

Scalability and Flexibility

As your business grows, so do your logistics needs. A 3PL with multiple locations can seamlessly scale operations to accommodate increased demand without compromising service quality.

Risk Mitigation

Geographic distribution minimizes risks associated with regional disruptions. Whether due to weather conditions or local events, having multiple centers ensures continued operations and consistent delivery performance.

Optimized Inventory Management

Strategically placed centers enable effective inventory distribution, reducing the need for excess stock while maintaining high service levels. Working with a 3PL will improve order picking accuracy and reduce picking and packing errors while creating a transparent overview leveraging a warehouse management system.

Enhanced Customer Satisfaction

Fast delivery times contribute significantly to customer satisfaction. By utilizing a network of fulfillment centers, you ensure a reliable and efficient service that meets customer expectations consistently.

Choosing a provider like One World Direct not only optimizes logistics but also enhances the end-to-end customer experience, positioning your business competitively in the e-commerce landscape.

FAQs About Selecting a Location for Your 3PL Fulfillment Center

What are the most important factors to consider when choosing a location for your fulfillment center?

Selecting the ideal site is critical to the efficiency of your logistics. Key considerations include:

- Proximity to Customers: Reduces delivery times and costs. Being closer to your customer base enhances satisfaction and retention.

- Transportation Infrastructure: Access to major highways, ports, and airports facilitates faster shipping and lowers transport costs.

- Labor Market: Availability of skilled labor can significantly impact operations. Evaluate local workforce quality and cost.

- Tax Incentives and Regulations: Local government incentives can reduce operational expenses, while compliance with regional regulations is non-negotiable.

How does having multiple fulfillment centers benefit my business?

Managing several fulfillment centers can transform logistics efficiency:

- Reduced Shipping Times: Multiple locations enable you to serve diverse markets promptly, reaching customers within two-day delivery windows.

- Cost Efficiency: Proximity reduces shipping costs, allowing competitive pricing without sacrificing margins.

- Risk Mitigation: A network of centers ensures business continuity in case one location faces disruptions due to unforeseen circumstances.

What role does technology play in optimizing logistics at different locations?

Technology integration is pivotal in streamlining operations across multiple sites:

- Data Analytics: Leverage insights to optimize inventory distribution and minimize stockouts.

- Real-Time Tracking Systems: Ensure transparency and accuracy in order processing by monitoring shipments live.

- Advanced Warehouse Management Systems (WMS): Automate tasks like inventory management and order picking for increased efficiency.

Investing in cutting-edge technology not only optimizes logistics but also enhances the overall customer experience by ensuring timely deliveries and accurate order fulfillment.

Partner with One World Direct for Strategic Advantage in Ecommerce Operations

Don’t select the right fulfillment center. Partner with us! We have multiple fulfillment centers across the country to ensure on-time delivery. We offer customizable fulfillment solutions to meet your exact needs. Leave the fulfillment to the experts and focus on what you do best. We will stay on top of emerging issues, such as new tariffs, and can help you deliver best-in-class service to all your shoppers.

One World Direct offers a distinct edge as a 3PL partner:

- Extensive Reach: With fulfillment centers strategically located across the U.S., you can reach 99% of customers within two days.

- Innovative Personalization: Our cutting-edge Personalized-to-Consumer (P2C) services like embroidery and engraving give your brand a competitive advantage.

- Comprehensive Solutions: From D2C to B2B, our tailored fulfillment services cater to diverse ecommerce needs.

Book a logistics consultation to learn ways to start lowering fulfillment costs while elevating your shipping experiences.

In This Article:

Subscribe to our Newsletter

Tincidunt urna mauris eu quam vulputate lobortis sit. Purus feugiat arcu nunc quisque massa ut.